Bag in Bag Out HEPA Filter Housing - Clean Air Solution

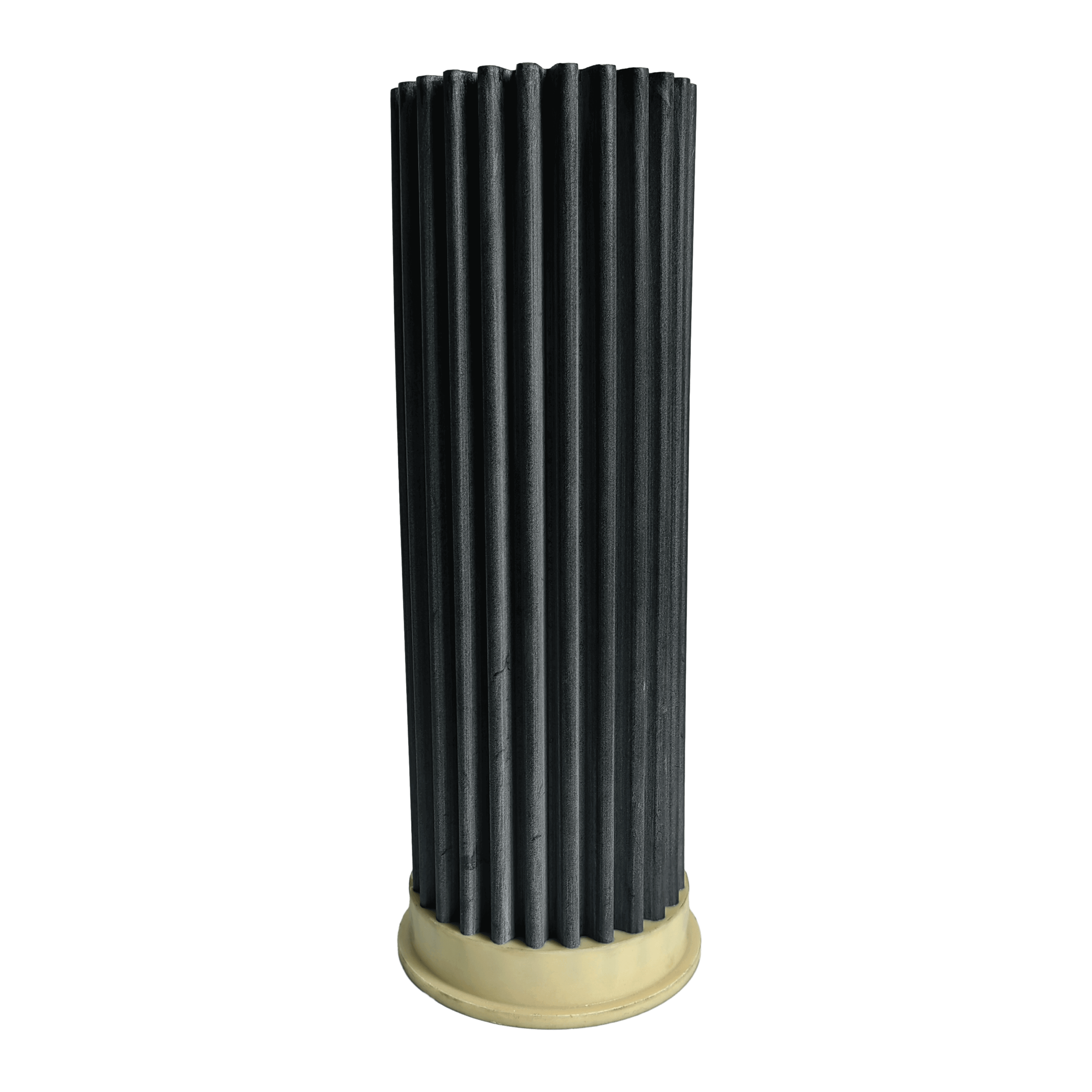

Introducing Our Bag in Bag Out HEPA Filter Housing

Our Bag in Bag Out HEPA Filter Housing is the ultimate solution for maintaining a clean and healthy environment in any industrial or commercial setting. This innovative product is designed to contain and remove hazardous particulates from the air, ensuring the safety of your employees and the integrity of your facility.

This HEPA filter housing features a unique bag in bag out system that allows for safe and easy filter replacement without the risk of contamination. The double-gasketed door ensures a tight seal, while the durable construction provides long-lasting performance. The user-friendly design makes maintenance a breeze, saving you time and hassle.

Our HEPA filter housing is not only practical, but also a great value. With its reliable performance and low maintenance requirements, it will save you money in the long run. Plus, by investing in this product, you are showing your employees and stakeholders that you prioritise their health and well-being.

With its high-quality materials and expert craftsmanship, our Bag in Bag Out HEPA Filter Housing is a product you can trust. It meets the highest industry standards for air filtration and containment, giving you peace of mind knowing that your facility is in compliance with regulations.

Say goodbye to air quality concerns with our Bag in Bag Out HEPA Filter Housing. With its easy maintenance, reliable performance, and exceptional value, it's the perfect addition to any industrial or commercial space.

Picture Show

Our Advantages

Hygienic Design

Sintered metal filters are designed with materials that meet food-grade hygiene standards. They are easy to clean and sanitize, preventing bacterial contamination and ensuring compliance with industry regulations.

Corrosion Resistance

Sinter metal filters are resistant to corrosion, ensuring their longevity and reliability even in harsh chemical environments. This property is crucial for maintaining the integrity of the filters in medical applications where exposure to various substances is common.

Durable Construction

Crafted from high-quality stainless steel, the pleated filter cartridge boasts exceptional durability.

Vision & Mission

Our vision is to be at the forefront of sintered metal fitter manufacturing, setting new benchmarks for excellence, innovation, and customer satisfaction.Guided by a mission to deliver cutting-edge filtration solutions, we strive to meet and exceed the diverse needs of our global clientele.

Q&A

What are Porous Metal Filters?

Porous metal filters stand as specialized filtering tools employed in applications where conventional filtration equipment falls short. Typically, metals undergo a sintering process, transforming them into porous or powdered structures, ensuring a more effective filtration process.

Technically, sintering is a metallurgical method applied to solidify metals or alloys into a powdered form. This involves heating the metal or alloy below its melting point to create an intense solid structure with a specific number of pores.

Here are some main types of porous filters used across various industrial applications:

• Sintered Porous Metal Filter: These filters boast pores for effective filtration and are crafted to withstand high pressure and mechanical stress. Manufacturing involves sintering plastic and high molecular polymer powder at elevated temperatures.

• Porous Stainless Steel: Utilizing grade 316 steel, these high-performance filters offer excellent pressure and temperature resistance, ideal for harsh conditions.

• Porous Discs: Shaped as filter discs, these filters are designed with precise pore sizes and numbers for efficiency in specific applications.

• Sintered Metal Filter: Tailored for high industrial and commercial demands, these filters accommodate the effective filtration of gases, liquids, and semi-solids.

• Porous Bronze Filter: Manufactured with spherical bronze powder, these filters excel in noise reduction and turbulence-proofing, making them a reliable choice across various industries.

What are Sintered Titanium Filters?

Sintered titanium filters are porous metal components created through a sintering process, designed to provide efficient filtration in various applications.

What are the typical applications of sintered plastic porous filters?

Sintered plastic porous filters are used in various industries, such as pharmaceuticals, food and beverage, water treatment, automotive, aerospace, and electronics, for filtration, separation, venting, and fluidization applications.

Can sintered porous filter discs withstand high temperatures?

Yes, depending on the material selected (e.g., stainless steel or nickel alloys), sintered porous filter discs can withstand high temperatures, making them suitable for applications involving elevated temperatures.

Stainless steel mesh filter

Stainless steel multi cartridge filter housing

Stainless Steel Duplex filter housing

Stainless steel air filter housing

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions