stainless steel filter water

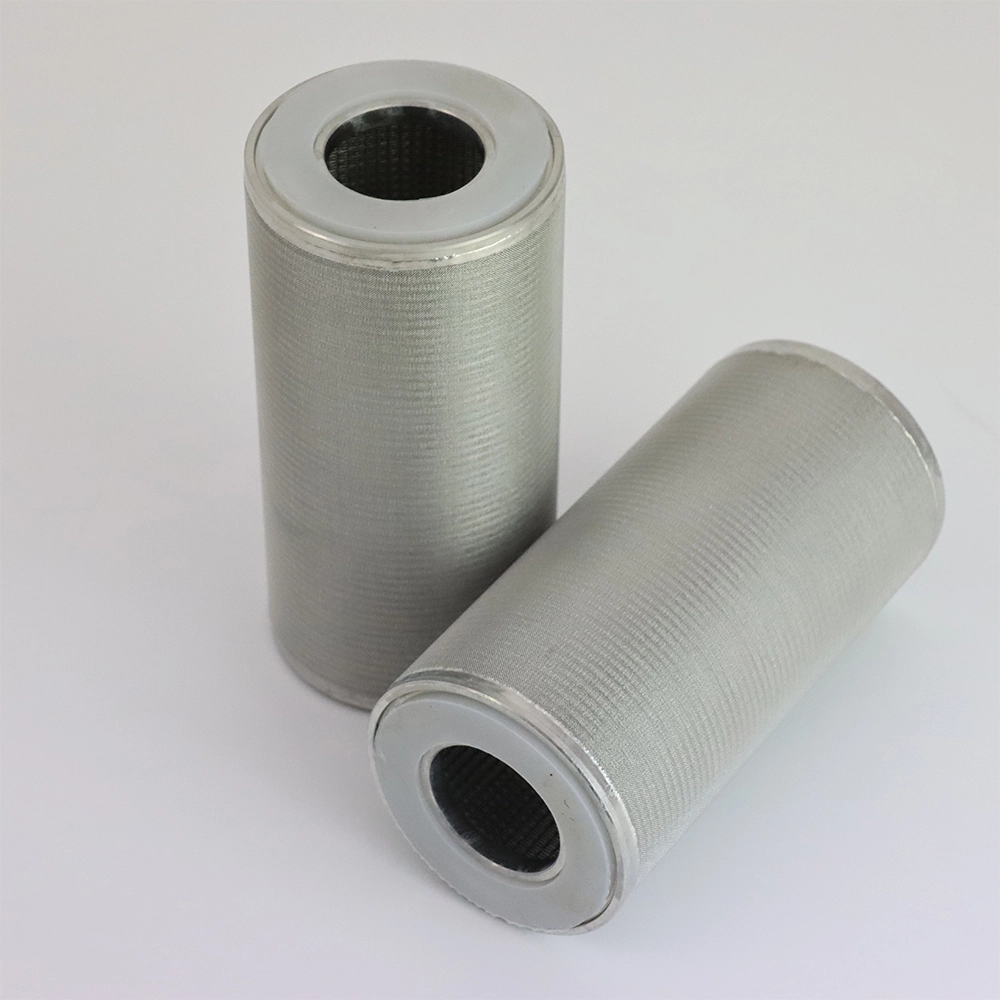

Lvyuan’s sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

![]() Personalized customization:

Personalized customization:

Whether choosing from these specifications or presenting your unique requirements, Lvyuan ensures a tailored approach to meet your specific needs.

![]() After-Sales Service and Warranty:

After-Sales Service and Warranty:

We offer comprehensive after-sales services, including installation guidance and technical support. Our products also come with a specified warranty period to ensure a worry-free experience for our customers.

Properties of Lvyuan sintered stainless steel filter

Lvyuan’s sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material. This filtration marvel, akin to its stainless steel filter cartridge counterpart, comprises essential components such as a filter tube, end caps, and an O-ring.

Distinguishing itself by utilizing 100% stainless steel, Lvyuan's commitment ensures the fabrication of sintered filter cartridges capable of withstanding elevated temperatures, resisting corrosion, and exhibiting robust mechanical strength. Positioned as an exemplary filtration component designed to eliminate impurities, sintered stainless steel filters find extensive utility in filtering gases, liquids, or solids.

Tailored to specific filtration needs

Lvyuan's stainless steel sintered filter cartridges stand as a testament to precision engineering, durability, and adaptability, making them indispensable across a spectrum of filtration challenges in gas, liquid, or solid mediums.

Stainless Steel Sintered Filter Features

Reasons to choose stainless steel sintered filter element

Sintered stainless steel filter Advantages

Stainless Steel Sintered Filter Cartridge Specifications

Explore the comprehensive parameters defining Lvyuan's stainless steel sintered filter cartridge, providing a foundation for versatile and reliable filtration solutions. Whether choosing from these specifications or presenting your unique requirements, Lvyuan ensures a tailored approach to meet your specific needs.

Applications of Stainless Steel Sintered Filter Cartridge

Lvyuan's Stainless Steel Sintered Filter Cartridges find versatile applications across various industries, owing to their robust design and high-performance filtration capabilities. Key applications include: water treatment, gas-liquid separation, steam filtration, high-temperature liquids and gases, catalyst recovery, chemical processing, oil filtration, pharmaceutical industry, food and beverage industry, and industrial filtration.

We’ve got answers.

Browse some answers to our most common questions, or you can drop us a line to ask something else.

Sintered Metal Filter

In which industries are industrial sintered metal filter cartridges commonly used?

These cartridges find applications in petrochemicals, pharmaceuticals, water treatment, food processing, automotive, aerospace, and many other industries where precise and reliable filtration is essential.

What is the temperature range that industrial sintered metal filter cartridges can handle?

The temperature range varies based on the material used, but they can typically withstand temperatures from -200°C to 1000°C or even higher for certain alloys.

How can I select the right industrial sintered filter cartridge for my application?

Consult with the manufacturer or supplier, providing details about your specific requirements, such as filtration needs, operating conditions, and industry standards, to receive guidance on selecting the most suitable cartridge for your application.

Can industrial sintered metal filter cartridges be customized?

Yes, these cartridges can be customized in terms of dimensions, filtration ratings, materials, and end connections to suit the specific needs of different industrial processes.

How often should industrial-sintered metal filter cartridges be replaced?

The replacement frequency depends on the operating conditions and the level of contaminants in the process. Regular inspection and monitoring help determine the optimal replacement schedule.

What is an industrial sintered metal filter cartridge?

An industrial sintered filter cartridge is a filtration component made through a sintering process, combining metal powders to create a porous structure. These cartridges are designed for industrial applications to remove contaminants from liquids and gases.

What materials are commonly used in industrial-sintered metal filter cartridges?

Common materials include stainless steel (304, 316, and 316L), bronze, Inconel, Monel, titanium, and other alloys, depending on the specific requirements of the application.

What are the key advantages of using industrial-sintered metal filter cartridges?

Advantages include high filtration efficiency, durability, wide temperature resistance, chemical compatibility, customization options, high flow rates, ease of cleaning, and versatility across various industries.

How often should industrial sintered metal filter cartridges be replaced?

The replacement frequency depends on the operating conditions and the level of contaminants in the process. Regular inspection and monitoring help determine the optimal replacement schedule.

What is the cleaning process for industrial sintered metal filter cartridges?

Cleaning methods include backwashing, ultrasonic cleaning, chemical cleaning, or a combination of these, depending on the type of contaminants and the cartridge material.

Want to talk to us

Get in touch

Please fill in the form below. We aim to reply within 1 business day.

Sintered powder metal filters

Sintered powder metal filters are crafted from compressed and sintered metal powders, forming a porous structure. Porosity: 28%-50% Permeability: 0.02-20L/cm²minPa Pressure Resistance: 0.5Mpa Temperature Resistance: Less than 280℃

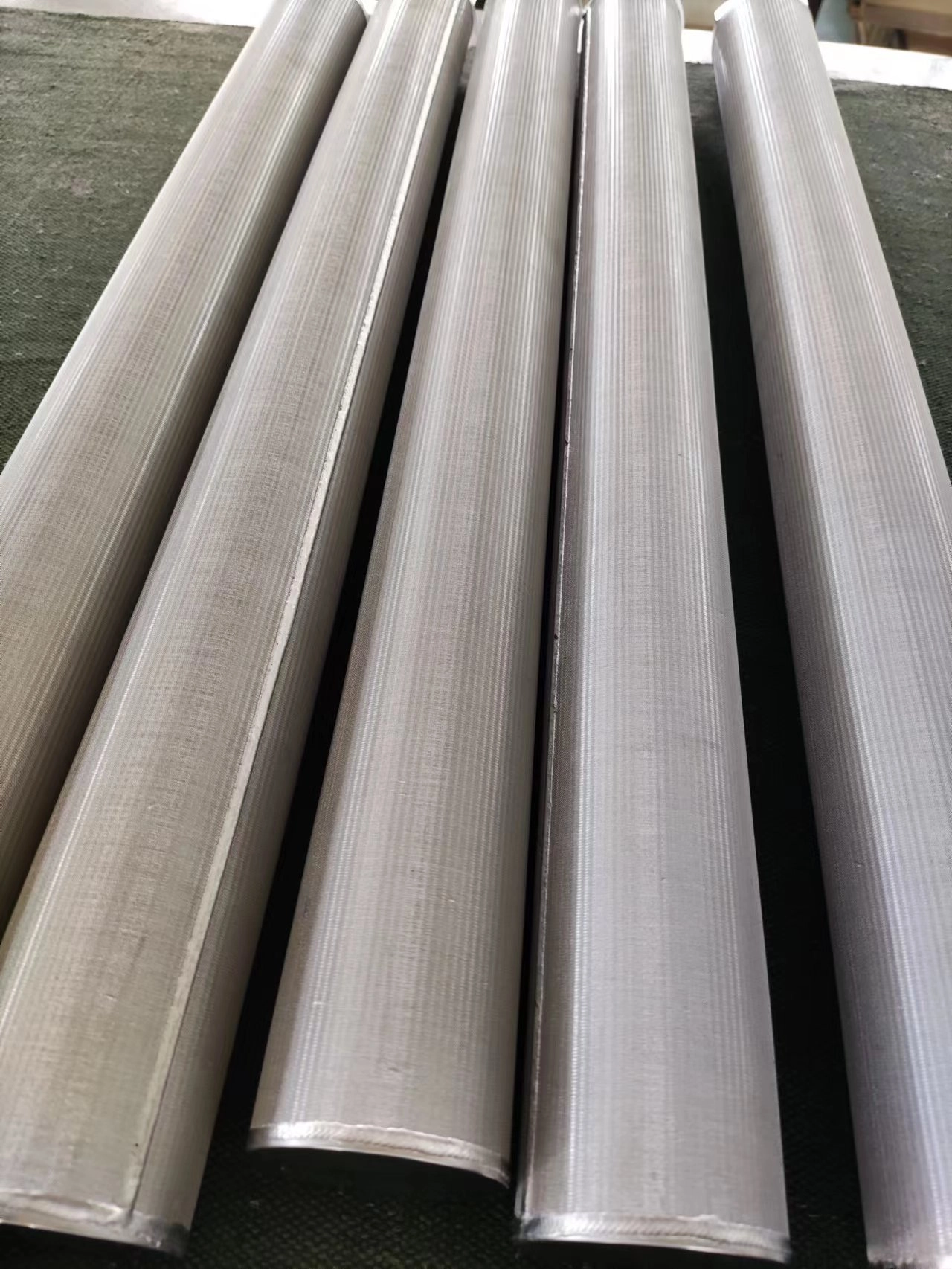

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Stainless steel pleated filter cartridge

Lvyuan Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

Sintered titanium filter

Discover the efficiency and versatility of Lvyuan's sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions