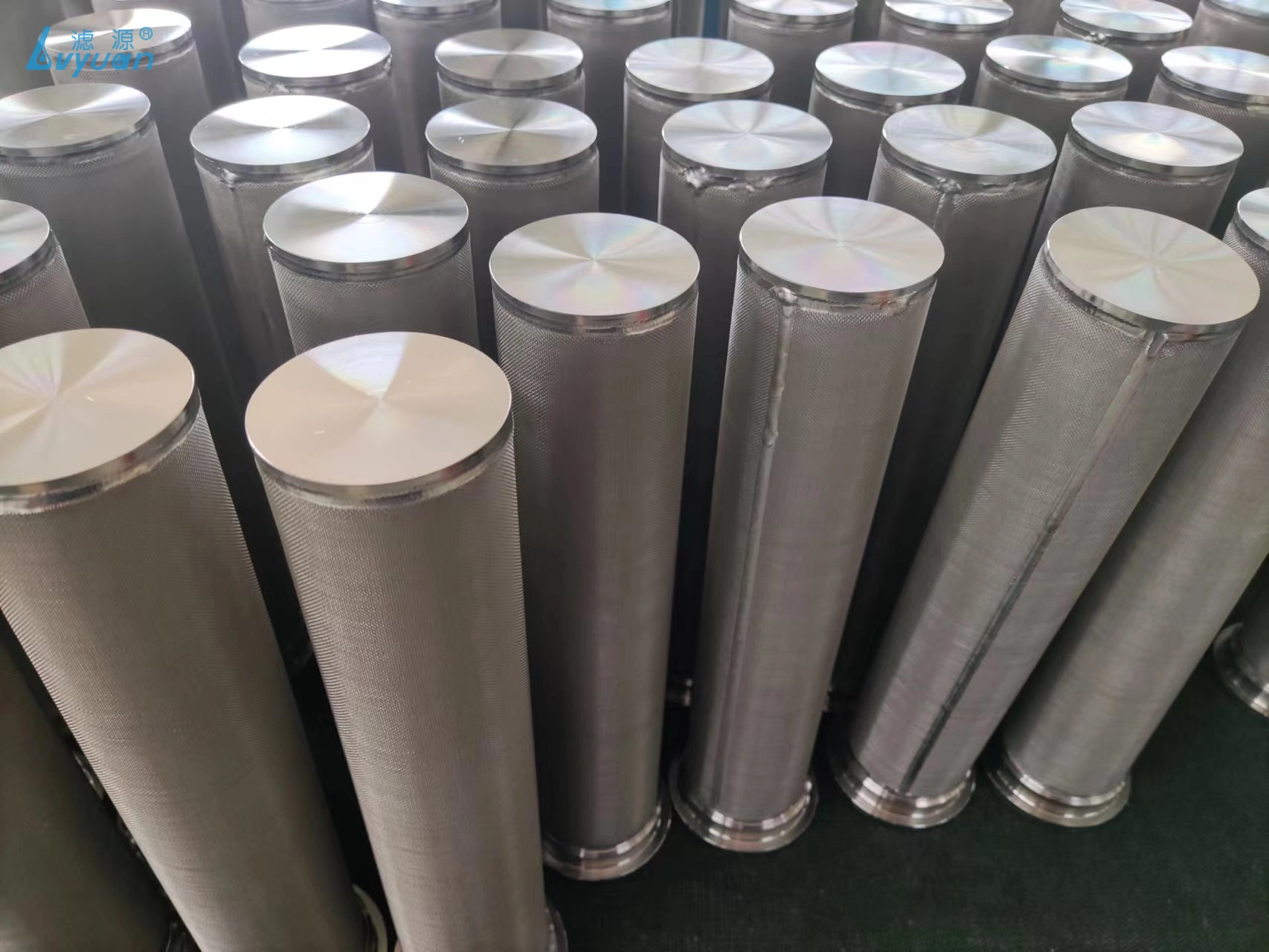

Case Study: 316L Sintered Powder Filter for a Spanish Customer

Customer Overview

A customer from Spain, operating in the chemical processing industry, required a high-performance filtration solution for their liquid filtration system. They needed a durable, corrosion-resistant filter that could provide precise particle filtration while maintaining excellent flow characteristics. The client requested 200 units of custom 316L sintered powder filters, with specific dimensions and filtration accuracy.

Product Specifications

Product Name: 316L Sintered Powder Filter

Material: Stainless Steel 316L (SS316L)

Length: 20 inches

Diameter: 50mm

Filtration Accuracy: 25µm

Quantity: 200 pieces

Challenges

The key challenge was to meet the customer’s stringent requirements for filtration accuracy and material durability. The filter had to efficiently remove contaminants sized 25 microns or larger while ensuring optimal flow rates within their chemical processing setup. Additionally, the filters had to withstand corrosive chemicals and high-pressure environments, making the choice of SS316L essential due to its resistance to corrosion and high temperatures.

Solution Provided

Material Selection: We chose 316L stainless steel, known for its superior corrosion resistance, particularly in chemical processing environments. SS316L also offers high durability under both high-pressure and high-temperature conditions, making it ideal for the customer's application.

Precision Filtration: Using advanced powder metallurgy techniques, we created a porous structure that met the 25µm filtration accuracy requirement. This enabled the filters to efficiently trap small particles while maintaining steady fluid flow.

Custom Dimensions: The customer needed a filter length of 20 inches and a diameter of 50mm. Our production team ensured that the sintered powder filters were manufactured to these precise dimensions, guaranteeing they would integrate seamlessly into the customer's existing filtration system.

Batch Consistency: Producing 50 identical units with the same high standard of quality was critical. We implemented stringent quality control checks at every stage of production to ensure that each filter met the required specifications for dimensional accuracy and filtration performance.

Testing & Validation: After production, the filters underwent rigorous testing for both filtration efficiency and mechanical durability. This included pressure testing to confirm their ability to withstand the operational pressures of the customer's system without compromising filtration performance.

Outcome

The 50 custom 316L sintered powder filters were successfully delivered to the customer in Spain, fulfilling all their requirements for size, material, and filtration accuracy. The filters have performed exceptionally well in their chemical processing application, offering reliable filtration of particulates while maintaining high flow rates. The use of SS316L material also ensured that the filters remained corrosion-free and durable, even in the harsh operating environment.

The customer was highly satisfied with the consistent quality of the filters, as well as the quick turnaround time for the order. This case highlights our ability to deliver high-precision, customized filtration solutions tailored to meet the specific demands of industrial customers.

How to Clean Sintered Metal Filters: A Comprehensive Guide

A Comprehensive Guide to Sintered Filters: Features, Production, and Benefits

Sintered Plastic Filters: A Comprehensive Guide

Sintered Metal Filters | Durable & Efficient Filtration Solutions

Sintered Activated Carbon Filters: Comprehensive Guide Introduction

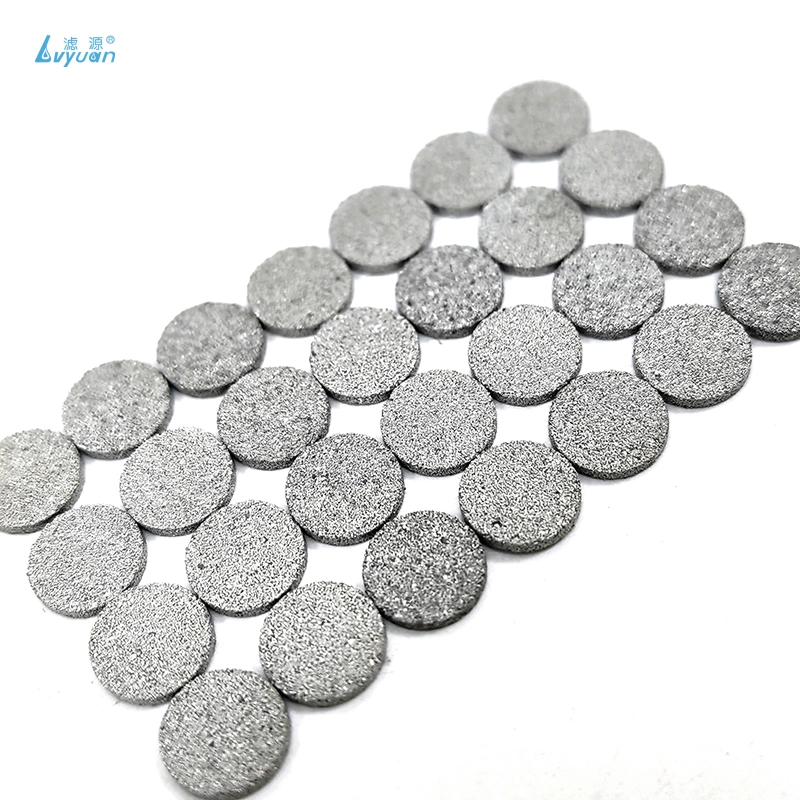

Case Study: Sintered Powder Disc for French Customer

Sintered Titanium Filters

Can Sintered Titanium Filters Withstand Harsh Environments?

Yes, sintered titanium filters exhibit excellent resistance to corrosion from seawater and various chemicals, making them suitable for harsh and aggressive environments.

How Do Sintered Titanium Filters Work?

Sintered titanium filters function by allowing fluid or gas to pass through their porous structure, capturing particles and impurities, resulting in effective filtration.

Are Sintered Titanium Filters Reusable?

Yes, sintered titanium filters support easy cleaning, enabling reusability and minimizing operational costs over their extended lifespan.

For company

Lvyuan main product advantages

• Quality Assurance:

Lvyuan prioritizes quality as a cornerstone of its operations. We adhere to rigorous quality control standards throughout the manufacturing process to ensure that our products meet the highest industry standards.

• Innovative Technology:

We leverage cutting-edge technologies in the design and production of our products. By staying at the forefront of technological advancements, we provide our customers with innovative solutions that meet their evolving needs.

• Diverse Product Range:

Lvyuan offers a comprehensive and diverse range of products, catering to various industries and applications. Our extensive product portfolio allows customers to find solutions tailored to their specific requirements.

• Customization Capabilities:

Recognizing the unique needs of our customers, we provide customizable options for our products. This ensures that our clients receive tailored solutions that align with their individual preferences and applications.

• Competitive Pricing:

We are committed to offering competitive prices without compromising on quality. Our cost-effective solutions enable customers to access high-quality products at reasonable and competitive market rates.

Sintered Metal Filters

What applications are sintered metal filters suitable for?

Sintered metal filters find applications in petrochemicals, water treatment, food and beverage, pharmaceuticals, automotive, and various industrial processes requiring precise filtration.

Titanium rod filter

Discover the efficiency and versatility of Lvyuan's titanium rod filter, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Y Type filter housing

The stainless steel y strainer comprises several key components, including a housing, a multi-element filter, a reverse flushing mechanism, a differential pressure controller, and others.

Stainless steel air filter housing

Lvyuan's Stainless Steel Air Filter Housing is crafted from high-grade stainless steel, ensuring durability and corrosion resistance for extended service life. With versatile configuration options and various size choices, our housing effectively accommodates different filtration needs.

Portable filtration system

Designed for versatility and convenience, Lvyuan stainless steel Portable Filtration System offers an efficient solution for on-the-go filtration needs. With its compact and lightweight design, this system is easily transportable and can be deployed in various environments, from industrial settings to remote locations.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

Sintered titanium filter

Discover the efficiency and versatility of Lvyuan's sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Stainless steel perforated filter

Lvyuan stainless steel Perforated filter is a new type of filter material processed by combining perforated plates with several layers of square mesh (or dense mesh) through sintering.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions