Sintered Plastic Filters: A Comprehensive Guide

This blog post provides a comprehensive overview of sintered plastic filters, including their construction, advantages, applications, and selection criteria. We discuss the various types of sintered plastic filters, their manufacturing process, and their role in industries such as chemical processing, food and beverage production, and environmental filtration. Additionally, we offer valuable insights on choosing the right sintered plastic filter for your specific needs.

Introduction

Sintered plastic filter have become an indispensable component in various industries due to their exceptional performance and versatility. In this comprehensive guide, we will delve into the intricacies of sintered plastic filters, exploring their construction, advantages, applications, and how to select the right filter for your specific needs.

Understanding Sintered Plastic Filters

Sintered plastic filters are porous materials created through a process called sintering, where plastic particles are heated and fused together to form a solid structure with interconnected pores. This unique construction allows for precise control of pore size, enabling effective filtration of particles and contaminants.

How Sintered Plastic Filters Are Made

The manufacturing process of sintered plastic filters involves several key steps:

- Particle Selection: High-quality plastic particles are chosen based on desired properties such as chemical resistance, temperature tolerance, and mechanical strength.

- Mixing and Blending: The selected particles are mixed and blended to achieve the desired pore size distribution and other characteristics.

- Molding: The mixture is molded into the desired shape, such as discs, cylinders, or cartridges.

- Sintering: The molded components are heated in a controlled environment to cause the particles to fuse together and form a porous structure.

Types of Sintered Plastic Filters

Sintered plastic filters are available in a wide variety of types, each with its own unique characteristics and applications:

- Depth Filters: These filters have a deep bed of porous material that captures particles throughout their depth.

- Surface Filters: These filters have a relatively thin porous layer that traps particles on the surface.

- Membrane Filters: These filters have a very fine pore size, allowing for the removal of extremely small particles.

Advantages of Sintered Plastic Filters

Sintered plastic filters offer numerous advantages that make them a popular choice in many industries:

- Durability and Longevity: Sintered plastic filters are highly resistant to corrosion, abrasion, and chemical attack, ensuring a long service life.

- High Filtration Efficiency: The precise control of pore size in sintered plastic filters allows for effective removal of contaminants, even at very low particle concentrations.

- Chemical Resistance: Sintered plastic filters are compatible with a wide range of chemicals and solvents, making them suitable for use in harsh environments.

- Lightweight and Easy to Handle: Sintered plastic filters are generally lightweight and easy to handle, reducing installation and maintenance costs.

Applications of Sintered Plastic Filters

Sintered plastic filters are used in a wide range of applications, including:

- Industrial Filtration: Chemical processing, food and beverage production, pharmaceutical manufacturing, oil and gas industry.

- Environmental Filtration: Water treatment, air purification.

- Medical and Laboratory Applications: Sterilization and filtration of fluids, diagnostic testing.

Choosing the Right Sintered Plastic Filter

When selecting a sintered plastic filter, it is important to consider the following factors:

- Filtration Requirements: What type and size of particles need to be removed?

- Chemical Compatibility: Will the filter be exposed to any chemicals or solvents?

- Operating Conditions: What are the temperature, pressure, and flow rate conditions?

- Cost-Effectiveness: What is the desired balance between performance and cost?

By carefully considering these factors, you can choose the sintered plastic filter that best meets your specific needs.

Conclusion

Sintered plastic filters are versatile and high-performance filtration solutions that offer numerous benefits in a wide range of industries. By understanding their construction, advantages, applications, and selection criteria, you can effectively utilize sintered plastic filters to improve the quality and efficiency of your filtration processes.

If you are looking for reliable and high-quality sintered plastic filters, Lvyuan is your trusted partner. With our expertise and commitment to customer satisfaction, we can provide you with the ideal filtration solutions for your specific needs. Contact us today to learn more about our product offerings and discuss your filtration requirements.

How to Clean Sintered Metal Filters: A Comprehensive Guide

A Comprehensive Guide to Sintered Filters: Features, Production, and Benefits

Sintered Metal Filters | Durable & Efficient Filtration Solutions

Sintered Activated Carbon Filters: Comprehensive Guide Introduction

Case Study: 316L Sintered Powder Filter for a Spanish Customer

Case Study: Sintered Powder Disc for French Customer

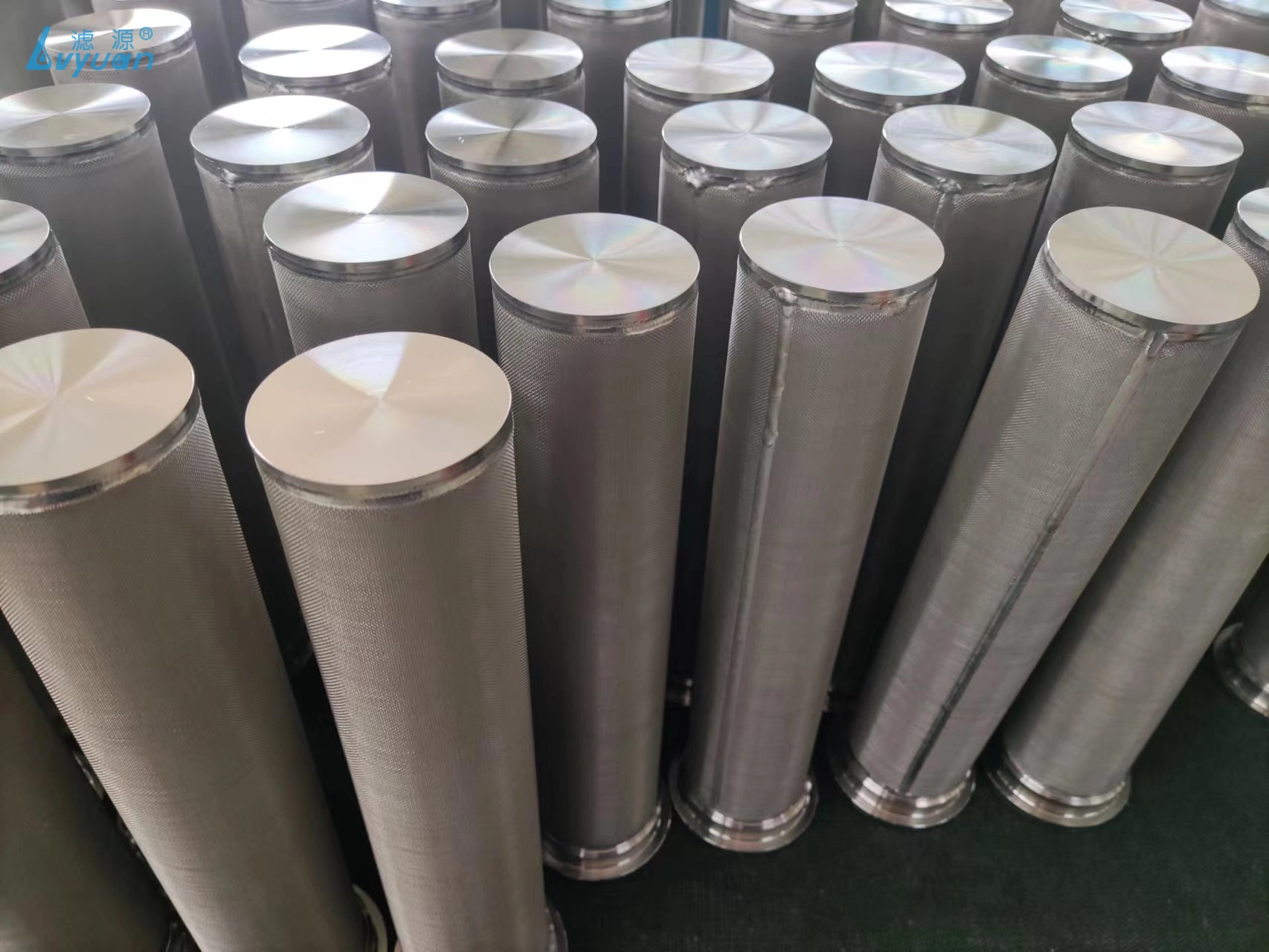

Stainless Steel Pleated Filter Cartridges

How often do these stainless steel pleated cartridges need maintenance?

Maintenance frequency depends on the specific application and operating conditions. However, these cartridges are designed for easy installation and maintenance, with cleaning procedures that contribute to their longevity.

Sintered Metal Filter

How can I select the right industrial sintered filter cartridge for my application?

Consult with the manufacturer or supplier, providing details about your specific requirements, such as filtration needs, operating conditions, and industry standards, to receive guidance on selecting the most suitable cartridge for your application.

Metal mesh filters

Can sintered wire mesh filter be customized?

Yes, sintered wire mesh can be customized in terms of material, pore size, thickness, and dimensions to suit specific filtration requirements. Customization allows for optimal performance in diverse applications.

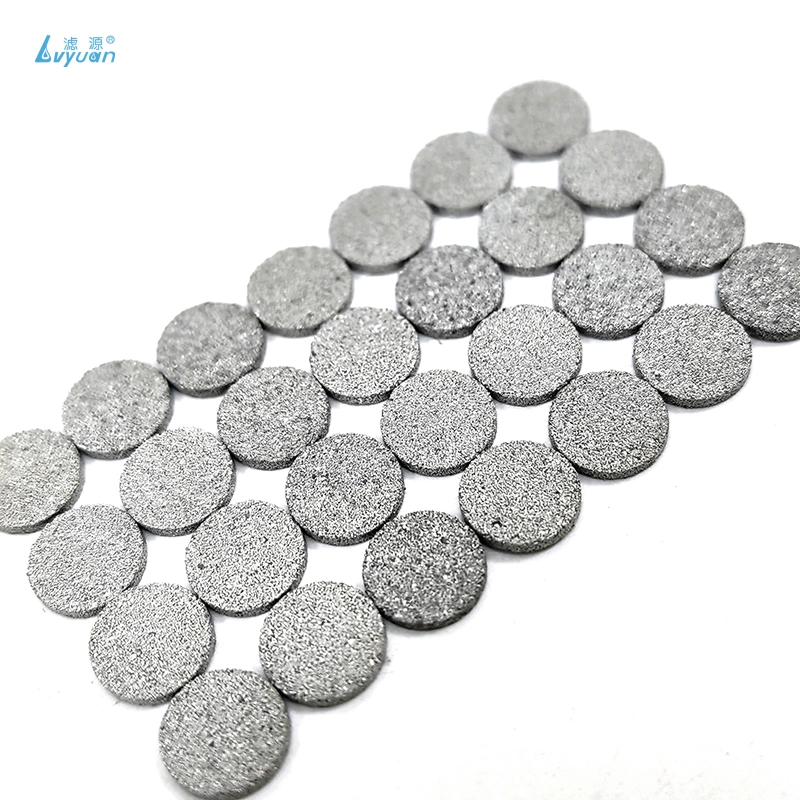

Sintered mesh filters

Can sintered mesh filters be used in corrosive environments?

Yes, sintered mesh filters can be manufactured from corrosion-resistant materials such as stainless steel, making them suitable for use in corrosive environments.

For customization

How can we guarantee quality?

Always take a pre-production sample before mass production.

Our state-of-the-art testing equipment and rigorous adherence to quality control standards ensure that our filter housings and filter elements comply with ISO 9001.

Titanium rod filter

Discover the efficiency and versatility of Lvyuan's titanium rod filter, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Y Type filter housing

The stainless steel y strainer comprises several key components, including a housing, a multi-element filter, a reverse flushing mechanism, a differential pressure controller, and others.

Stainless steel air filter housing

Lvyuan's Stainless Steel Air Filter Housing is crafted from high-grade stainless steel, ensuring durability and corrosion resistance for extended service life. With versatile configuration options and various size choices, our housing effectively accommodates different filtration needs.

Portable filtration system

Designed for versatility and convenience, Lvyuan stainless steel Portable Filtration System offers an efficient solution for on-the-go filtration needs. With its compact and lightweight design, this system is easily transportable and can be deployed in various environments, from industrial settings to remote locations.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

Sintered titanium filter

Discover the efficiency and versatility of Lvyuan's sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Stainless steel perforated filter

Lvyuan stainless steel Perforated filter is a new type of filter material processed by combining perforated plates with several layers of square mesh (or dense mesh) through sintering.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions