What is a sintered glass filter used for and the advantages?

Discover the unique benefits of the Lvyuan sintered glass filter in our latest article. Explore how this exceptional filtration solution enhances industrial and laboratory processes by offering superior chemical resistance, high temperature durability, and efficient particle retention. Perfect for challenging environments, the glass sintered filter ensures reliable performance and longevity. Dive into the advantages and applications of using Lvyuan’s sintered glass filter to optimize your filtration needs. Unlock the potential of cutting-edge filtration technology today.

A sintered glass filter is used primarily for filtration and separation in various laboratory and industrial applications. Made from finely ground glass particles that are fused together through a sintering process, these filters have a porous structure that allows fluids to pass through while trapping solid particles.

Common Uses of Sintered Glass Filters:

1. Chemical Filtration: Sintered glass filters are often used to filter out solid impurities from chemical solutions, ensuring the purity of the liquid.

2. Vacuum Filtration: In laboratory settings, they are used in vacuum filtration systems to remove particulate matter from liquids, such as during the preparation of samples for analysis.

3. Gas Filtration: Sintered glass filters can be used to remove particulate contaminants from gases in both laboratory and industrial processes.

5. Crystallization: They are employed in crystallization processes to separate crystals from the mother liquor.

Environmental Testing: Sintered glass filters are used to filter out particulate matter from water, air, and soil samples in environmental monitoring.

6. Sterilization: These filters can be used to sterilize liquids and gases by removing microorganisms when fine enough pores are used.

Solvent Filtration: In organic synthesis and other chemical processes, they help in filtering solvents to remove any impurities that could affect the reaction.

The advantages of sintered glass

Sintered glass offers several advantages, making it a popular choice in various applications, particularly in laboratory and industrial settings. Here are some of the key benefits:

1. High Chemical Resistance

Sintered glass is highly resistant to chemical corrosion, making it suitable for use with a wide range of acids, bases, and solvents. This property is particularly valuable in chemical laboratories and industries where exposure to harsh chemicals is common.

2. Precise Filtration

The sintering process creates a uniform and consistent pore structure in the glass, allowing for precise filtration. This makes sintered glass filters ideal for applications requiring the separation of fine particles from liquids or gases, ensuring high filtration accuracy.

3. High Thermal Stability

Sintered glass can withstand high temperatures without degrading or losing its structural integrity. This makes it suitable for use in processes that involve heating or where temperature fluctuations are common.

4. Reusability and Longevity

Sintered glass filters are durable and can be cleaned and reused multiple times without losing their effectiveness. This reusability not only reduces waste but also makes them a cost-effective option over time.

5. Mechanical Strength

The sintering process enhances the mechanical strength of the glass, making it less prone to breakage compared to traditional glass. This increased strength allows sintered glass to withstand higher pressures during filtration processes.

6. Inertness

Sintered glass is chemically inert, meaning it does not react with the substances it comes into contact with. This property is essential in applications where maintaining the purity of the filtered material is critical.

7. Versatility

Sintered glass can be used in a wide range of applications, from chemical filtration and gas purification to environmental testing and laboratory analysis. Its versatility makes it a valuable material in both scientific and industrial contexts.

8. Easy to Clean

Sintered glass filters are relatively easy to clean, often requiring just a simple rinse or backwash to remove trapped particles. This ease of maintenance further contributes to their long-term usability.

How to Clean Sintered Metal Filters: A Comprehensive Guide

A Comprehensive Guide to Sintered Filters: Features, Production, and Benefits

Sintered Plastic Filters: A Comprehensive Guide

Sintered Metal Filters | Durable & Efficient Filtration Solutions

Sintered Activated Carbon Filters: Comprehensive Guide Introduction

Case Study: 316L Sintered Powder Filter for a Spanish Customer

For company

How do you establish a long-term and positive business relationship?

We maintain high-quality standards and competitive prices to ensure mutual benefits for our customers. We treat every customer with respect, considering them not only as clients but also as friends. We engage in sincere business dealings and aim to build lasting friendships, regardless of their geographical location.

For customization

How can we guarantee quality?

Always take a pre-production sample before mass production.

Our state-of-the-art testing equipment and rigorous adherence to quality control standards ensure that our filter housings and filter elements comply with ISO 9001.

Porous Plastic Filter

How do I choose the right sintered porous filter disc for my application?

Consider factors such as the nature of the substances being filtered, operating conditions (temperature, pressure), chemical compatibility, and desired filtration precision. Consulting with filtration experts can help guide the selection process.

For products

How can I request a quote or get more information about your sintered metal filters?

For inquiries, quotes, or additional information about our sintered metal filters, please contact our sales team through our website or by reaching out to [contact information]. We are happy to assist you with any questions or requirements you may have.

Sintered Titanium Filters

Do Sintered Titanium Filters Offer High Flow Rates?

Yes, sintered titanium filters support high flow rates at low-pressure drops, optimizing efficiency and ensuring consistent filtration performance.

Titanium rod filter

Discover the efficiency and versatility of Lvyuan's titanium rod filter, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Y Type filter housing

The stainless steel y strainer comprises several key components, including a housing, a multi-element filter, a reverse flushing mechanism, a differential pressure controller, and others.

Stainless steel air filter housing

Lvyuan's Stainless Steel Air Filter Housing is crafted from high-grade stainless steel, ensuring durability and corrosion resistance for extended service life. With versatile configuration options and various size choices, our housing effectively accommodates different filtration needs.

Portable filtration system

Designed for versatility and convenience, Lvyuan stainless steel Portable Filtration System offers an efficient solution for on-the-go filtration needs. With its compact and lightweight design, this system is easily transportable and can be deployed in various environments, from industrial settings to remote locations.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

Sintered titanium filter

Discover the efficiency and versatility of Lvyuan's sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Stainless steel perforated filter

Lvyuan stainless steel Perforated filter is a new type of filter material processed by combining perforated plates with several layers of square mesh (or dense mesh) through sintering.

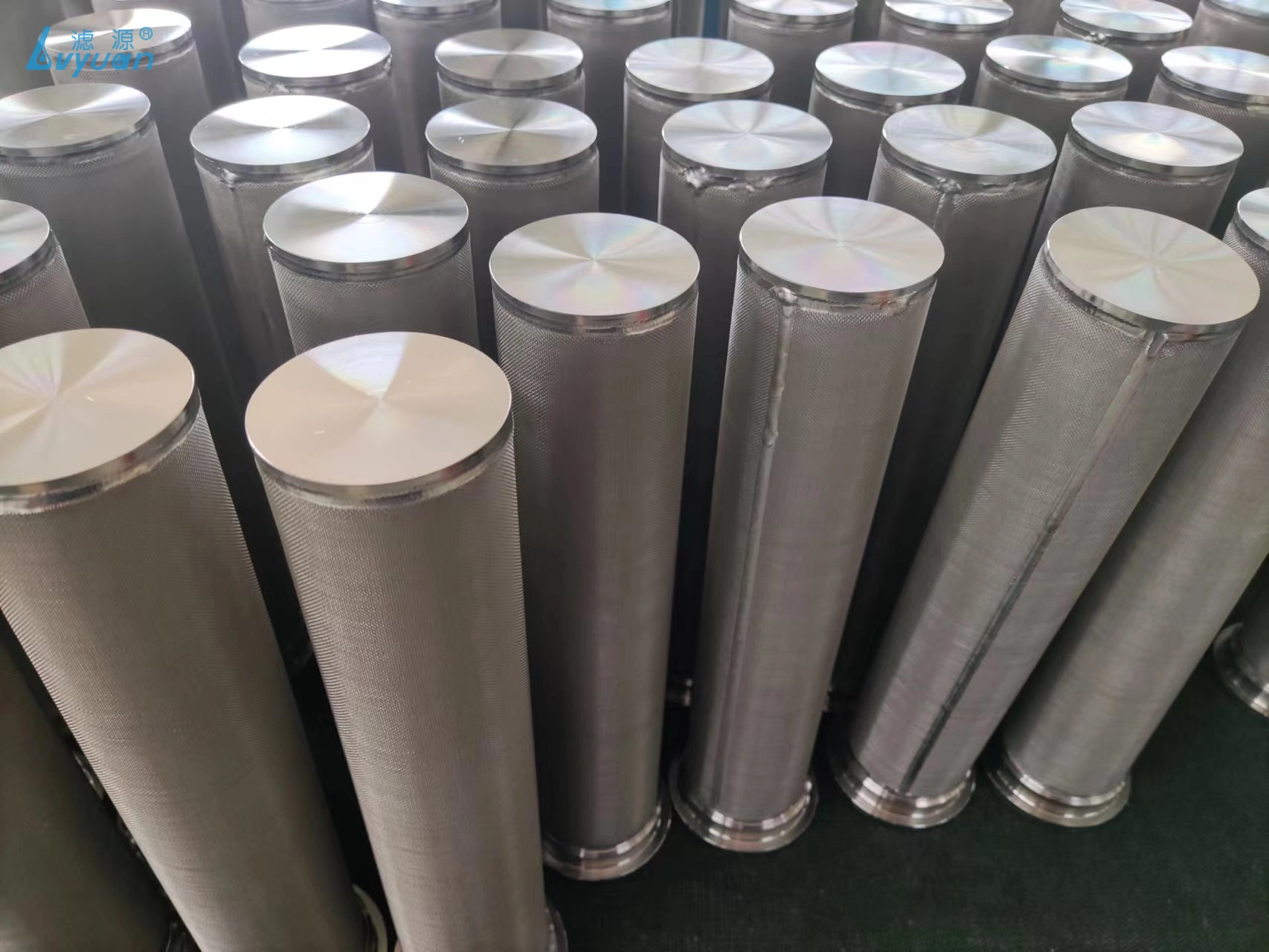

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions