How to Clean a Sintered Metal Filter?

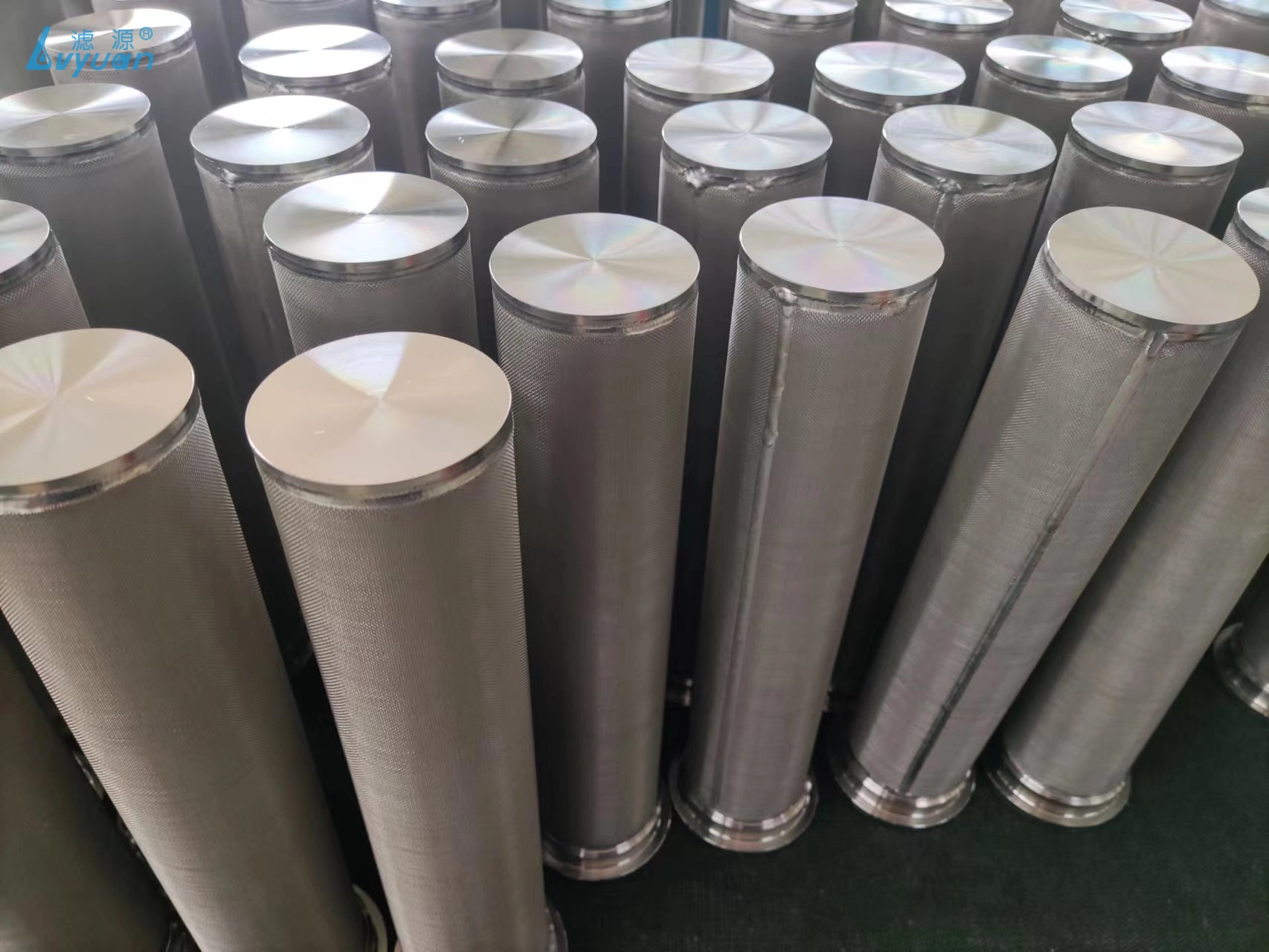

Sintered metal filters are durable and efficient, often used in various industrial and laboratory applications. Proper cleaning is essential to maintain their performance and extend their lifespan

Sintered metal filters are durable and efficient, often used in various industrial and laboratory applications. Proper cleaning is essential to maintain their performance and extend their lifespan. Here’s a step-by-step guide on how to clean a sintered metal filter:

1. Clean a Sintered Metal Filter Preparation

Safety First

Wear appropriate personal protective equipment (PPE) such as gloves, safety goggles, and a mask to protect yourself from any harmful substances or debris.

Gather Supplies

Cleaning solvent (e.g., acetone, isopropyl alcohol, or a specialized filter cleaner)

Ultrasonic cleaner (if available)

Compressed air or nitrogen

Soft brush

Container for soaking

2. Sintered Metal Filter Initial Inspection and Cleaning

Remove the Filter

Carefully remove the filter from the system, following the manufacturer’s instructions to avoid damaging it or the system.

Brush Off Loose Debris

Use a soft brush to gently remove any loose debris or particles from the surface of the filter.

Rinse with Solvent

Rinse the filter with a suitable solvent to remove surface contaminants. Ensure that the solvent is compatible with the material of the filter.

3. Sintered Metal Filter Deep Cleaning

Soak in Cleaning Solution

Place the filter in a container filled with the cleaning solvent. Allow it to soak for a specified period, typically between 30 minutes to several hours, depending on the level of contamination.

Ultrasonic Cleaning (Optional)

For a more thorough cleaning, use an ultrasonic cleaner. Fill the ultrasonic cleaner with the cleaning solution and place the filter inside. Run the cleaner for 15-30 minutes to dislodge any embedded particles.

Rinse Thoroughly

After soaking or ultrasonic cleaning, rinse the filter thoroughly with clean solvent to remove any remaining contaminants.

4. Sintered Metal Filter Drying

Blow Out Residual Solvent

Use compressed air or nitrogen to blow out any residual solvent from the filter. Ensure that the air pressure is not too high to avoid damaging the filter.

Air Dry

Allow the filter to air dry completely in a clean, dust-free environment. This ensures that no moisture or solvent remains trapped inside the filter.

5. Final Inspection and Reinstallation

Inspect for Cleanliness and Damage

Inspect the Sintered Metal filter carefully to ensure that it is clean and free from any damage. Check for any signs of wear or structural integrity issues.

Reinstall the Filter

Once the filter is completely dry and inspected, reinstall it into the system according to the manufacturer’s instructions.

6. Sintered Filter Maintenance Tips

Regular Cleaning Schedule

Establish a regular cleaning schedule based on the filter’s usage and the level of contamination in your system to maintain optimal performance.

Proper Storage

If the filter is not being used immediately after cleaning, store it in a clean, dry environment to prevent contamination.

Conclusion

Cleaning a sintered metal filter involves careful handling and appropriate cleaning methods to ensure its longevity and effectiveness. By following these steps, you can maintain your filter in excellent condition, ensuring reliable performance in your applications.

How to Clean Sintered Metal Filters: A Comprehensive Guide

A Comprehensive Guide to Sintered Filters: Features, Production, and Benefits

Sintered Plastic Filters: A Comprehensive Guide

Sintered Metal Filters | Durable & Efficient Filtration Solutions

Sintered Activated Carbon Filters: Comprehensive Guide Introduction

Case Study: 316L Sintered Powder Filter for a Spanish Customer

Stainless Steel Pleated Filter Cartridges

Are these pleat cartridges corrosion-resistant?

Yes, the use of stainless steel (SS 304 or SS 316L) provides excellent corrosion resistance, making the cartridges suitable for applications where exposure to corrosive substances is a concern.

For customization

Can you produce according to the samples or drawings?

Yes, we can produce your samples or technical drawings. We can build the molds and fixtures.

Sintered Powder Filters

Can sintered powder filters be used in high-temperature applications?

Yes, sintered powder filters are designed to withstand high temperatures. The choice of material, such as stainless steel or other heat-resistant alloys, contributes to their temperature resistance.

Sintered Metal Filter

What is the cleaning process for industrial sintered metal filter cartridges?

Cleaning methods include backwashing, ultrasonic cleaning, chemical cleaning, or a combination of these, depending on the type of contaminants and the cartridge material.

For company

How do you establish a long-term and positive business relationship?

We maintain high-quality standards and competitive prices to ensure mutual benefits for our customers. We treat every customer with respect, considering them not only as clients but also as friends. We engage in sincere business dealings and aim to build lasting friendships, regardless of their geographical location.

Titanium rod filter

Discover the efficiency and versatility of Lvyuan's titanium rod filter, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Y Type filter housing

The stainless steel y strainer comprises several key components, including a housing, a multi-element filter, a reverse flushing mechanism, a differential pressure controller, and others.

Stainless steel air filter housing

Lvyuan's Stainless Steel Air Filter Housing is crafted from high-grade stainless steel, ensuring durability and corrosion resistance for extended service life. With versatile configuration options and various size choices, our housing effectively accommodates different filtration needs.

Portable filtration system

Designed for versatility and convenience, Lvyuan stainless steel Portable Filtration System offers an efficient solution for on-the-go filtration needs. With its compact and lightweight design, this system is easily transportable and can be deployed in various environments, from industrial settings to remote locations.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

Sintered titanium filter

Discover the efficiency and versatility of Lvyuan's sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Stainless steel perforated filter

Lvyuan stainless steel Perforated filter is a new type of filter material processed by combining perforated plates with several layers of square mesh (or dense mesh) through sintering.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions