What is a sintered metal filter and benefits

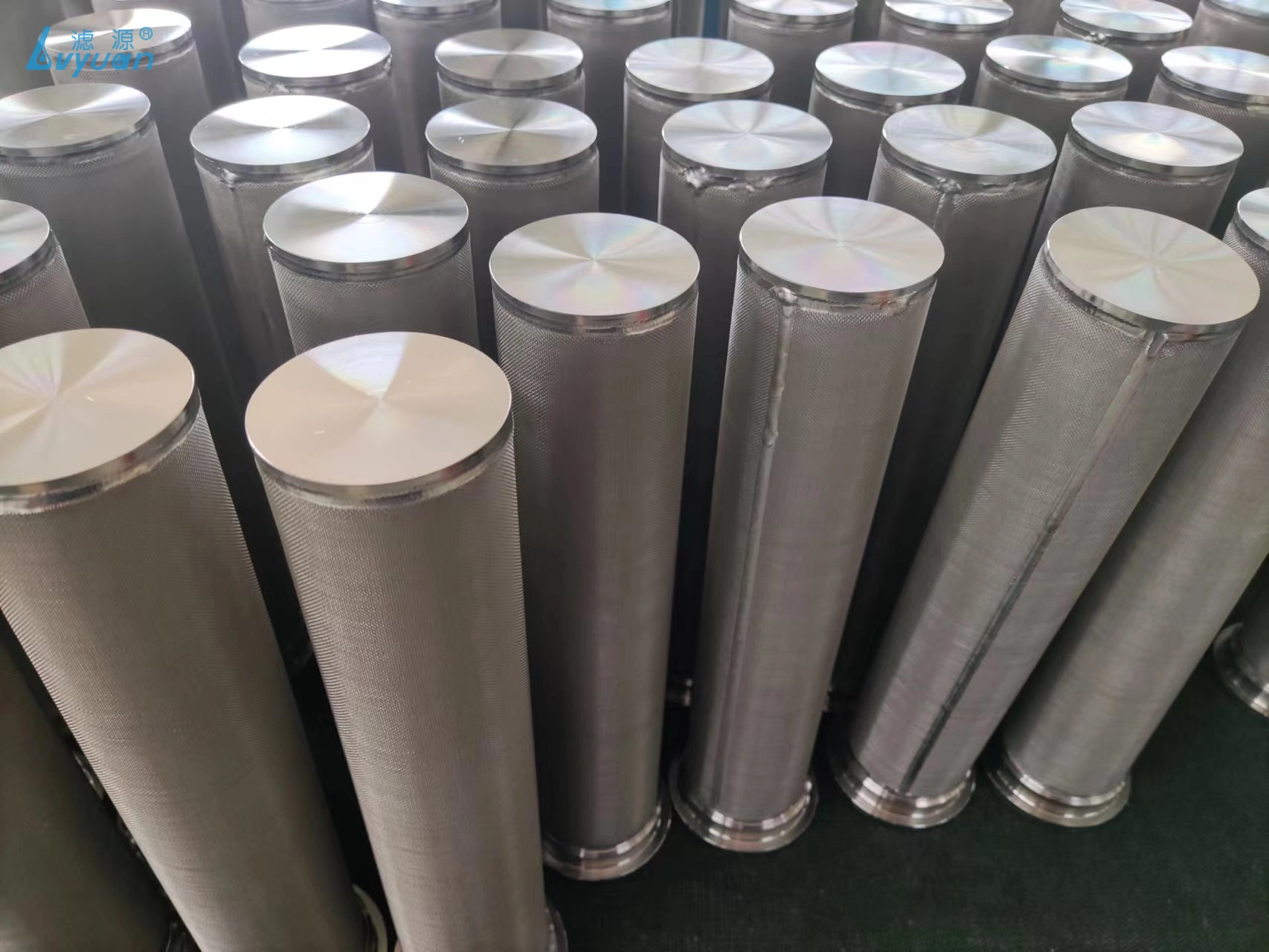

Discover the innovative world of sintered metal filters with Lvyuan. Our sintered metal filter technology offers superior durability, high filtration efficiency, and exceptional resistance to temperature and pressure. Ideal for a wide range of industrial applications, these metal sintered filters provide reliable performance and long-lasting service life. Experience the benefits of enhanced fluid purity and reduced maintenance costs. Trust Lvyuan for cutting-edge filtration solutions. Explore more about our sintered metal filters today.

Sintered metal filters are advanced filtration components widely used in various industries for their durability, efficiency, and ability to withstand extreme conditions. This article explores what sintered metal filters are, their benefits, applications, and how they are manufactured.

Definition and Structure

A sintered metal filter is a porous filter made from metal powders that are fused together using a process called sintering. This process involves heating the metal powders to a temperature below their melting point until they bond to form a rigid, porous structure. The resulting filter has a high degree of structural integrity and excellent filtration properties.

Benefits of Sintered Metal Filters

Durability and Strength

High Mechanical Strength: Sintered metal filters are robust and can withstand high pressures and mechanical stresses, making them suitable for demanding applications.

Resistance to Wear: These filters are highly resistant to wear and tear, ensuring a long service life even in harsh conditions.

Superior Filtration Efficiency

Fine Filtration:The controlled pore size of sintered metal filters allows for precise filtration of particles, providing high filtration efficiency.

Consistency: The uniform pore structure ensures consistent filtration performance over time.

Chemical and Thermal Resistance

Corrosion Resistance: Sintered metal filters are resistant to corrosion, making them suitable for use with aggressive chemicals and corrosive environments.

High Temperature Tolerance: These filters can operate at high temperatures, making them ideal for applications involving extreme heat.

Ease of Maintenance and Cleaning

Reusability: Sintered metal filters can be cleaned and reused multiple times, reducing replacement costs.

Backwashing Capability: Many sintered metal filters can be cleaned through backwashing, which involves reversing the flow of fluid to dislodge trapped particles.

Applications of Sintered Metal Filters

Industrial Filtration

Chemical Processing: Used to filter aggressive chemicals and corrosive fluids in the chemical processing industry.

Petrochemical Industry: Employed in the filtration of oils, gases, and other fluids in the petrochemical sector.

Water Treatment

Drinking Water Filtration: Used in water treatment plants to remove impurities and contaminants from drinking water.

Wastewater Treatment: Applied in wastewater treatment facilities to filter solids and pollutants from wastewater.

Pharmaceutical and Food Industries

Sterile Filtration: Used in the pharmaceutical industry for sterile filtration of drugs and biologics.

Food and Beverage Filtration: Employed in the food and beverage industry to ensure product purity and safety.

Automotive and Aerospace

Fuel and Oil Filtration: Used in automotive and aerospace applications to filter fuel, oil, and hydraulic fluids.

Air Filtration: Applied in air filtration systems to remove contaminants from intake and exhaust air.

Manufacturing Process of Sintered Metal Filters

Powder Preparation

Selection of Metal Powders: High-purity metal powders, such as stainless steel, bronze, or nickel, are selected based on the desired properties of the filter.

Mixing: The metal powders are mixed to achieve a uniform distribution of particle sizes.

Compaction

Molding: The metal powder mixture is placed in a mold and compacted under high pressure to form a green (unsintered) shape.

Pre-Sintering: The green shape may undergo a pre-sintering step to enhance its mechanical strength.

Sintering

Heating: The compacted shape is heated in a sintering furnace at a temperature below the melting point of the metal powders. This causes the particles to bond together.

Controlled Atmosphere: The sintering process is carried out in a controlled atmosphere to prevent oxidation and ensure the desired properties of the filter.

Post-Sintering Operations

Machining: The sintered filter may undergo machining to achieve the final dimensions and specifications.

Surface Treatment: Surface treatments, such as polishing or coating, may be applied to enhance the filter's performance.

Conclusion

Sintered metal filters are versatile and durable filtration solutions used across various industries for their superior filtration efficiency, mechanical strength, and resistance to harsh conditions. Their ability to be cleaned and reused makes them cost-effective and environmentally friendly. Understanding the benefits and applications of sintered metal filters can help in selecting the right filter for specific needs, ensuring efficient and reliable filtration.

How to Clean Sintered Metal Filters: A Comprehensive Guide

A Comprehensive Guide to Sintered Filters: Features, Production, and Benefits

Sintered Plastic Filters: A Comprehensive Guide

Sintered Metal Filters | Durable & Efficient Filtration Solutions

Sintered Activated Carbon Filters: Comprehensive Guide Introduction

Case Study: 316L Sintered Powder Filter for a Spanish Customer

For company

How do you establish a long-term and positive business relationship?

We maintain high-quality standards and competitive prices to ensure mutual benefits for our customers. We treat every customer with respect, considering them not only as clients but also as friends. We engage in sincere business dealings and aim to build lasting friendships, regardless of their geographical location.

Porous Plastic Filter

In what industries are sintered porous filter discs commonly used?

They are widely used in industries such as petrochemicals, pharmaceuticals, water treatment, food and beverage, automotive, and more, owing to their versatility and effective filtration capabilities.

What types of polymers are used to manufacture sintered plastic porous filters?

Common polymers used in the production of sintered plastic porous filters include polyethylene (PE), polypropylene (PP), polytetrafluoroethylene (PTFE), and polyvinylidene fluoride (PVDF), among others.

Sintered Powder Filters

What materials are commonly used in sintered powder filters?

Common materials include stainless steel (316L, 304L), bronze, Inconel®, Nickel, Monel®, Titanium, and other alloys. The material choice depends on the specific application's requirements.

For products

What sizes and shapes are available?

Our sintered metal filters come in a variety of sizes and shapes to meet different application needs. Common configurations include cylindrical, disc, and tube shapes, with customizable dimensions to fit specific requirements.

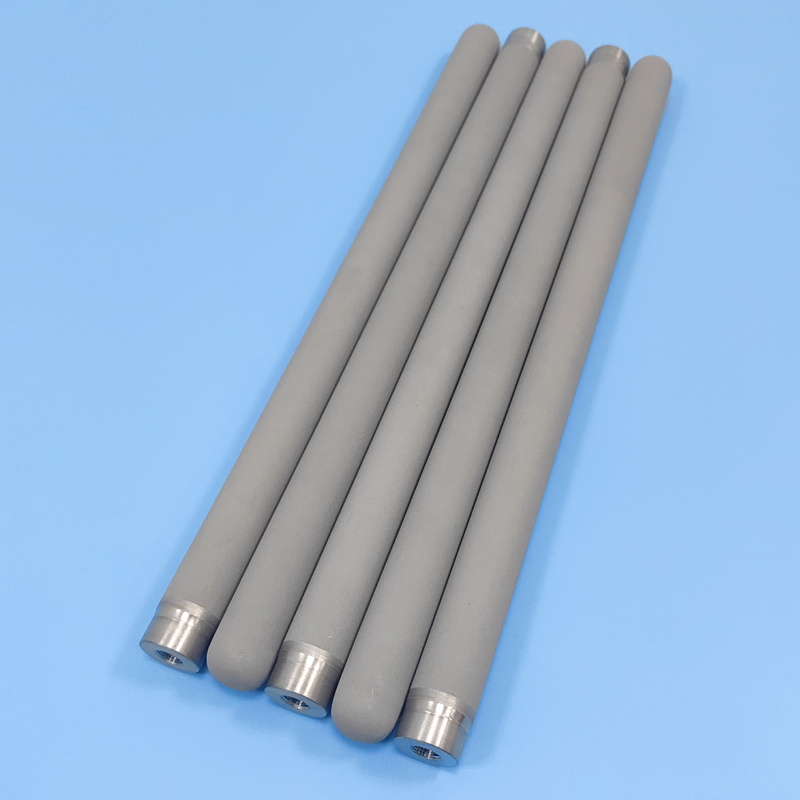

Titanium rod filter

Discover the efficiency and versatility of Lvyuan's titanium rod filter, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Y Type filter housing

The stainless steel y strainer comprises several key components, including a housing, a multi-element filter, a reverse flushing mechanism, a differential pressure controller, and others.

Stainless steel air filter housing

Lvyuan's Stainless Steel Air Filter Housing is crafted from high-grade stainless steel, ensuring durability and corrosion resistance for extended service life. With versatile configuration options and various size choices, our housing effectively accommodates different filtration needs.

Portable filtration system

Designed for versatility and convenience, Lvyuan stainless steel Portable Filtration System offers an efficient solution for on-the-go filtration needs. With its compact and lightweight design, this system is easily transportable and can be deployed in various environments, from industrial settings to remote locations.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

Sintered titanium filter

Discover the efficiency and versatility of Lvyuan's sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Stainless steel perforated filter

Lvyuan stainless steel Perforated filter is a new type of filter material processed by combining perforated plates with several layers of square mesh (or dense mesh) through sintering.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions