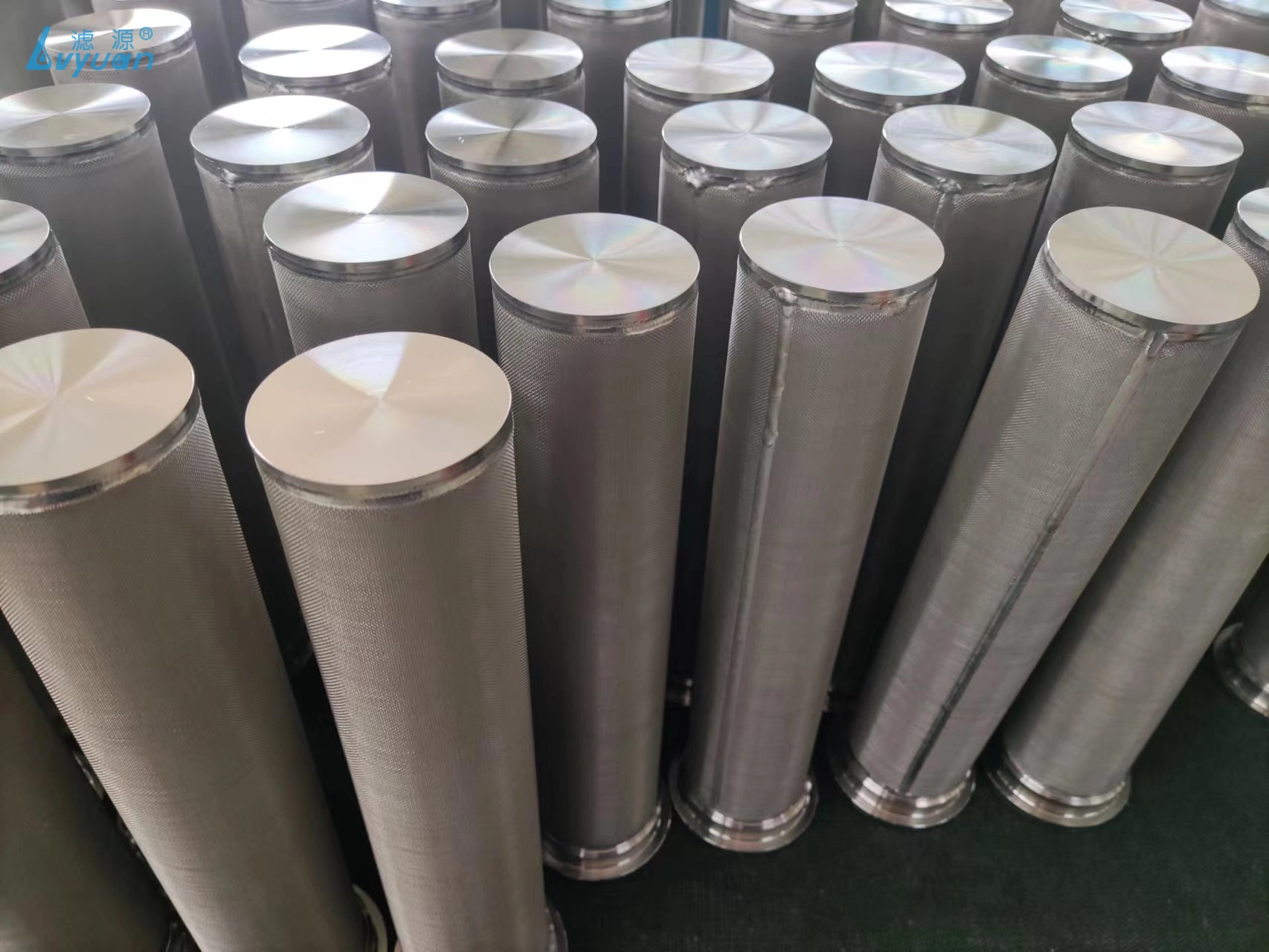

Advantages of Sintered Felt Filter Cartridges

Sintered felt filter cartridges are widely used filter elements in industries such as industrial, pharmaceuticals, food processing, electronic manufacturing, and more. They come with several significant advantages, making them an ideal choice for efficient filtration and liquid/gas separation.

Sintered felt filter cartridges are widely used as filter elements in industries such as industrial, pharmaceutical, food processing, electronic manufacturing, and more. They come with several significant advantages, making them an ideal choice for efficient filtration and liquid-gas separation. Below are the key advantages of sintered felt filter cartridges:

1. High Filtration Precision:

Sintered felt filter cartridges offer exceptional filtration precision, effectively removing particles, microorganisms, and impurities at the submicron level. This is crucial in industries requiring highly pure liquids or gases, such as pharmaceuticals, electronic manufacturing, and biotechnology.

2. Efficient Filtration:

Due to their microporous structure, sintered felt filter cartridges have a large filtration surface area, enabling them to process a significant volume of fluid in a short time, providing efficient filtration performance.

3. Corrosion Resistance:

Sintered felt filter cartridges can be made from different materials to adapt to various chemical environments and media. This makes them useful for filtering corrosive liquids or gases.

4. High-Temperature Resistance:

Some sintered felt filter cartridges can withstand high temperatures, making them effective in the filtration of high-temperature gases or liquids. This is widely applied in the metal smelting, refining, and chemical industries.

5. Long service life:

Sintered felt filter cartridges typically have a longer lifespan due to their wear resistance, making them less prone to damage or clogging. This reduces the frequency of replacements and lowers maintenance costs.

6. Cleaning and Reusability:

Sintered felt filter cartridges can be cleaned and reused, contributing to material savings and waste reduction. Self-cleaning sintered felt filter cartridges can be periodically backwashed to remove clogged impurities.

7. Customizability:

Sintered felt filter cartridges can be customized according to the requirements of different applications, including pore size, material selection, and outer dimensions. This makes them suitable for various filtration tasks.

8. Applicable to Multiple Media:

Sintered felt filter cartridges are not only suitable for liquid filtration but can also be used for gas filtration, expanding their application range.

9. Compliance with Industry Standards:

Sintered felt filter cartridges often comply with multiple industry standards and regulations, such as FDA (U.S. Food and Drug Administration) and CE (European Conformity), making them suitable for applications requiring high quality and compliance.

How to Clean Sintered Metal Filters: A Comprehensive Guide

A Comprehensive Guide to Sintered Filters: Features, Production, and Benefits

Sintered Plastic Filters: A Comprehensive Guide

Sintered Metal Filters | Durable & Efficient Filtration Solutions

Sintered Activated Carbon Filters: Comprehensive Guide Introduction

Case Study: 316L Sintered Powder Filter for a Spanish Customer

For customization

How can we guarantee quality?

Always take a pre-production sample before mass production.

Our state-of-the-art testing equipment and rigorous adherence to quality control standards ensure that our filter housings and filter elements comply with ISO 9001.

Sintered Metal Filters

Can sintered metal filters be customized for specific applications?

Yes, sintered metal filters can be customized based on shape, size, material, filtration accuracy, and other specifications to meet the unique requirements of different applications.

Porous Plastic Filter

What are the typical applications of sintered plastic porous filters?

Sintered plastic porous filters are used in various industries, such as pharmaceuticals, food and beverage, water treatment, automotive, aerospace, and electronics, for filtration, separation, venting, and fluidization applications.

In what industries are sintered porous filter discs commonly used?

They are widely used in industries such as petrochemicals, pharmaceuticals, water treatment, food and beverage, automotive, and more, owing to their versatility and effective filtration capabilities.

Sintered Titanium Filters

What Micron Ratings Are Available for Sintered Titanium Filters?

Sintered titanium filters are available in a wide range of micron ratings and configurations, offering tailored solutions for optimal performance across diverse applications.

Titanium rod filter

Discover the efficiency and versatility of Lvyuan's titanium rod filter, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Y Type filter housing

The stainless steel y strainer comprises several key components, including a housing, a multi-element filter, a reverse flushing mechanism, a differential pressure controller, and others.

Stainless steel air filter housing

Lvyuan's Stainless Steel Air Filter Housing is crafted from high-grade stainless steel, ensuring durability and corrosion resistance for extended service life. With versatile configuration options and various size choices, our housing effectively accommodates different filtration needs.

Portable filtration system

Designed for versatility and convenience, Lvyuan stainless steel Portable Filtration System offers an efficient solution for on-the-go filtration needs. With its compact and lightweight design, this system is easily transportable and can be deployed in various environments, from industrial settings to remote locations.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

Sintered titanium filter

Discover the efficiency and versatility of Lvyuan's sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Stainless steel perforated filter

Lvyuan stainless steel Perforated filter is a new type of filter material processed by combining perforated plates with several layers of square mesh (or dense mesh) through sintering.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions