Sintered Powder Metal Filters: A Deep Dive into Filtration Excellence

Filtration is a critical aspect of many industrial processes, requiring precision, efficiency, and reliability. Among the diverse array of filtration solutions, sintered powder metal filters emerge as an innovative and effective choice, offering a deep dive into filtration excellence. Let's explore the intricacies and advantages that make sintered powder metal filters stand out in the realm of filtration technology.

Filtration is a critical aspect of many industrial processes, requiring precision, efficiency, and reliability. Among the diverse array of filtration solutions, sintered powder metal filters emerge as an innovative and effective choice, offering a deep dive into filtration excellence. Let's explore the intricacies and advantages that make sintered powder metal filters stand out in the realm of filtration technology.

The Basics of Sintered Powder Metal Filters

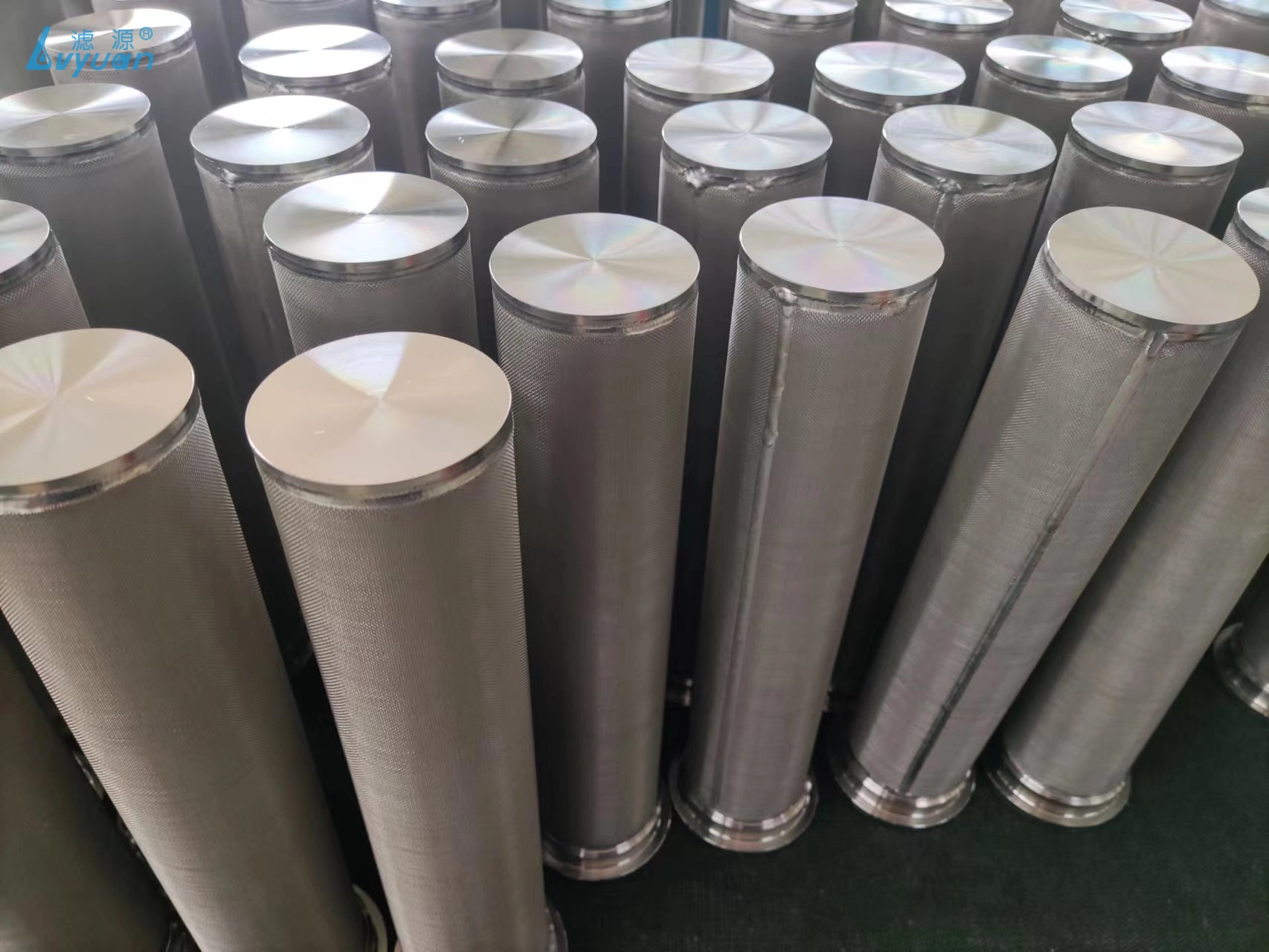

At the heart of sintered powder metal filters lies a meticulous manufacturing process. Fine metal powders, often composed of stainless steel or other alloys, are carefully selected for their specific properties. These powders undergo a sintering process where they are heated to a controlled temperature, allowing the particles to bond and form a porous structure. The result is a highly versatile and customizable filter media.

1. Precision Pore Control:

One of the key strengths of sintered powder metal filters lies in their ability to achieve precise control over pore sizes. This level of precision allows for tailoring the filter to capture particles of specific dimensions, ensuring optimal filtration for diverse applications. Whether it's capturing fine particulate matter or microbes, sintered powder metal filters offer unparalleled control.

2. Versatility in Material Selection:

Sintered powder metal filters can be crafted from various materials, providing flexibility to match the filter to the specific requirements of the application. This versatility makes them suitable for applications ranging from aggressive chemical environments to high-temperature processes.

3. Enhanced Strength and Durability:

The sintering process not only creates a porous structure but also enhances the strength and durability of the filter. This robust construction ensures a long lifespan and the ability to withstand challenging operating conditions without compromising filtration efficiency.

4. Efficient Fluid Flow:

The interconnected pores in sintered powder metal filters facilitate efficient fluid flow. This characteristic is particularly valuable in applications where maintaining a steady flow rate is crucial, such as in chemical processing, oil and gas, or pharmaceutical manufacturing.

5. Wide-ranging Applications:

Sintered powder metal filters find applications across diverse industries, including petrochemical, pharmaceutical, food and beverage, and more. Their adaptability, combined with high filtration precision, makes them a go-to solution for processes where purity and efficiency are paramount.

6. Sustainability through Reusability:

In an era of increasing environmental awareness, sintered powder metal filters shine with their potential for reuse. Many variants can be cleaned, regenerated, and reused, contributing to sustainability efforts by reducing waste and resource consumption.

Conclusion: Elevating Filtration Standards

Sintered powder metal filters are not just components; they represent the pinnacle of filtration excellence. Their precision, adaptability, and durability make them indispensable in industries where filtration is a mission-critical process. As technology evolves, a deep dive into the world of sintered powder metal filters continues to reveal new possibilities and elevate filtration standards across diverse industrial landscapes.

How to Clean Sintered Metal Filters: A Comprehensive Guide

A Comprehensive Guide to Sintered Filters: Features, Production, and Benefits

Sintered Plastic Filters: A Comprehensive Guide

Sintered Metal Filters | Durable & Efficient Filtration Solutions

Sintered Activated Carbon Filters: Comprehensive Guide Introduction

Case Study: 316L Sintered Powder Filter for a Spanish Customer

Sintered Powder Filters

What is a sintered powder filter?

A sintered powder filter is a porous filtration medium created by compacting and sintering metal powders. It is designed to provide efficient and precise filtration in various industrial applications.

Sintered mesh filters

Can sintered mesh filters be customized for specific requirements?

Yes, sintered mesh filters are highly customizable. They can be tailored based on factors such as filtration rating, material composition (e.g., stainless steel, monel), dimensions, and shape to meet the unique needs of different applications.

Stainless Steel Cartridge Filter Housing

What are the benefits of using stainless steel cartridge filter housings?

Stainless steel cartridge filter housings offer corrosion resistance, durability, and hygiene, making them suitable for use in a wide range of industries, including food and beverage, pharmaceuticals, chemicals, and water treatment.

Sintered Titanium Filters

Do Sintered Titanium Filters Offer High Flow Rates?

Yes, sintered titanium filters support high flow rates at low-pressure drops, optimizing efficiency and ensuring consistent filtration performance.

How Can Machinability of Sintered Titanium Filters be improved?

Machinability can be enhanced by selecting high-speed machining tools, creating conducive cutting environments, and using high-quality cutting tools to optimize cost, surface finishing, and integrity.

Titanium rod filter

Discover the efficiency and versatility of Lvyuan's titanium rod filter, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Y Type filter housing

The stainless steel y strainer comprises several key components, including a housing, a multi-element filter, a reverse flushing mechanism, a differential pressure controller, and others.

Stainless steel air filter housing

Lvyuan's Stainless Steel Air Filter Housing is crafted from high-grade stainless steel, ensuring durability and corrosion resistance for extended service life. With versatile configuration options and various size choices, our housing effectively accommodates different filtration needs.

Portable filtration system

Designed for versatility and convenience, Lvyuan stainless steel Portable Filtration System offers an efficient solution for on-the-go filtration needs. With its compact and lightweight design, this system is easily transportable and can be deployed in various environments, from industrial settings to remote locations.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

Sintered titanium filter

Discover the efficiency and versatility of Lvyuan's sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Stainless steel perforated filter

Lvyuan stainless steel Perforated filter is a new type of filter material processed by combining perforated plates with several layers of square mesh (or dense mesh) through sintering.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions