Choosing the Right Sintered Metal Filter for Your Needs

When it comes to efficient filtration, sintered metal filters are often the unsung heroes. These robust, versatile components play a crucial role in numerous industries. But what exactly are they, and why are they so important? Let's dive into the world of sintered metal filters and explore their many facets.

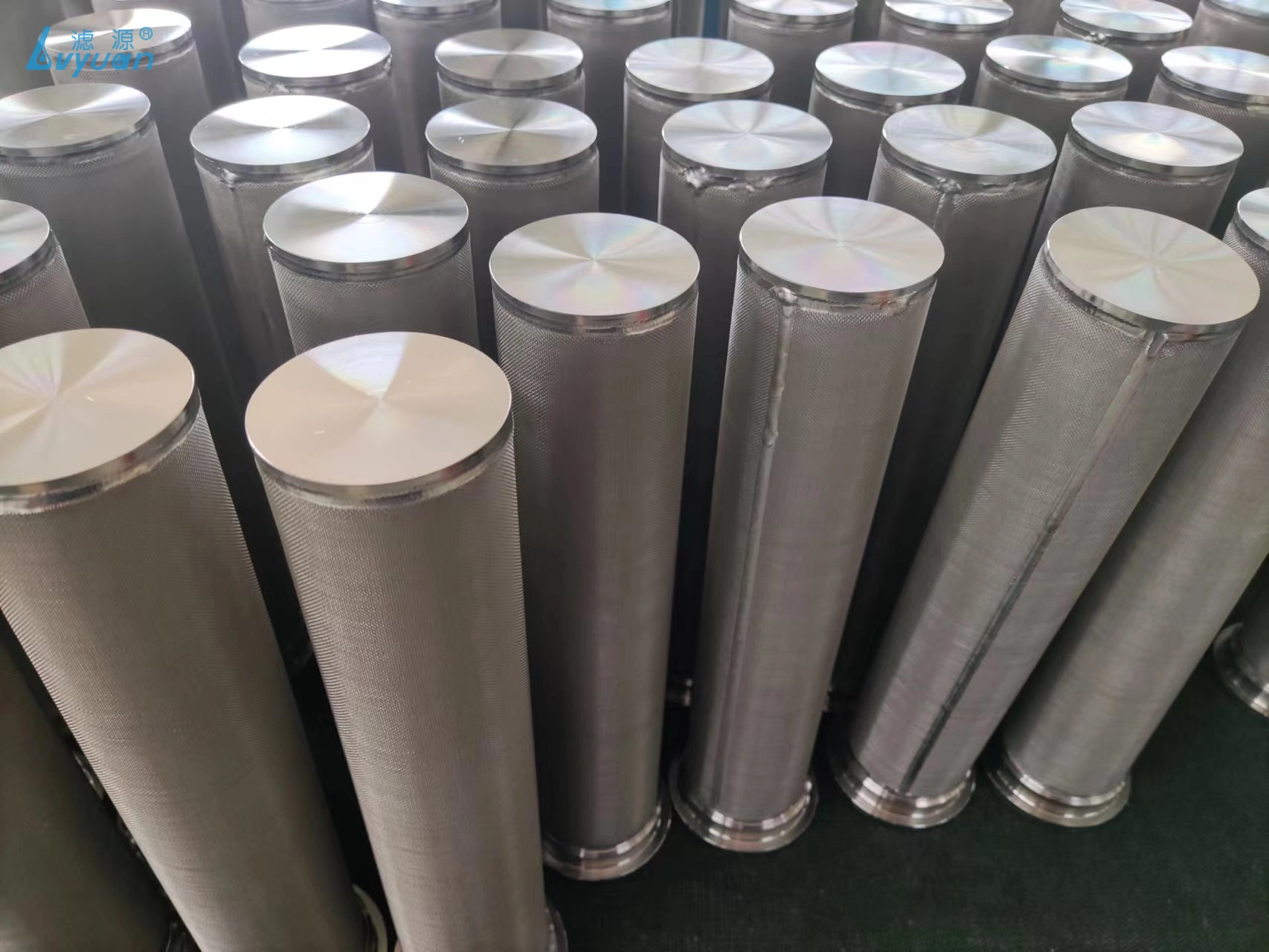

What is a Sintered Metal Filter?

A sintered metal filter is a type of filter made by compressing metal powders and then heating them to just below their melting point. This process, known as sintering, fuses the particles together without melting them, creating a porous structure that can filter out contaminants from gases and liquids.

How Sintered Metal Filters Work?

Sintered metal filters are highly effective filtration devices made by fusing metal powder particles through a sintering process. This process creates a porous structure that allows fluids to pass through while capturing particles and contaminants. Here's a detailed look at how sintered metal filters work:

1. Manufacturing Process:

Powder Selection: Metal powders such as stainless steel, bronze, nickel, or titanium are chosen based on the desired properties of the final filter.

Pressing: The metal powder is compacted into a desired shape and size using a mold.

Sintering: The compacted metal powder is heated in a controlled environment below its melting point, causing the particles to bond together, forming a solid but porous structure.

2. Filtration Mechanism:

Porosity: The sintered process creates interconnected pores within the metal matrix. The size and distribution of these pores can be controlled during manufacturing to achieve specific filtration ratings.

Surface Filtration: Larger particles are trapped on the surface of the filter.

Depth Filtration: Smaller particles penetrate the surface and are captured within the porous structure. This dual mechanism enhances the filter's capacity and efficiency.

3. Filtration Process:

Fluid Flow: The contaminated fluid (liquid or gas) enters the filter housing and flows through the sintered metal filter element.

Particle Capture: As the fluid passes through the pores, particles larger than the pore size are captured on the surface or within the filter matrix.

Clean Fluid: The filtered fluid exits the filter housing, free of the trapped contaminants.

4. Advantages:

Durability: Sintered metal filters are robust and can withstand high pressures, temperatures, and corrosive environments.

Reusability: They can be cleaned and reused multiple times, making them cost-effective in the long run.

Customization: Pore size, shape, and filter geometry can be tailored to specific applications.

Efficiency: High filtration efficiency due to the uniform pore structure.

5. Applications:

Industrial: Used in chemical processing, petrochemical, and oil & gas industries for filtration of liquids and gases.

Aerospace: Employed in fuel and hydraulic systems to ensure contaminant-free fluids.

Pharmaceutical: Used in processes requiring sterile filtration.

Food and Beverage: Applied in the filtration of liquids to ensure product purity.

Water Treatment: Used in water purification systems to remove particulates and contaminants.

6. Maintenance and Cleaning:

Backwashing: For liquid filtration systems, reverse flow (backwashing) can remove trapped particles.

Ultrasonic Cleaning: High-frequency sound waves can dislodge particles from the filter matrix.

Chemical Cleaning: Certain solvents can be used to dissolve and remove contaminants without damaging the filter.

Choosing the Right Sintered Metal Filter

Application Requirements

Selecting the right sintered metal filter starts with understanding the specific needs of your application. Consider factors like the type of fluid or gas being filtered, operating conditions, and required filtration efficiency. Matching the filter material and design to these requirements ensures optimal performance.

Budget Considerations

While sintered metal filters might have a higher upfront cost compared to traditional filters, their long-term benefits often justify the investment. Consider the total cost of ownership, including maintenance, replacement frequency, and potential downtime, when making your decision.

Cleaning Methods

Proper maintenance of sintered metal filters is crucial for their longevity. Regular cleaning can be done using ultrasonic baths, backflushing, or chemical cleaning agents, depending on the filter material and the nature of the contaminants. Ensuring the filter is thoroughly cleaned prevents clogs and maintains efficiency.

Longevity Tips

To extend the life of your sintered metal filter, follow manufacturer guidelines for maintenance and avoid exposing the filter to conditions beyond its specified limits. Regular inspections and timely cleaning will keep your filter in top condition, ensuring consistent performance.

Future of Sintered Metal Filters

Technological Advancements

The field of sintered metal filtration is continuously evolving with advancements in materials science and manufacturing techniques. New alloys and sintering methods are being developed to enhance the performance and expand the applications of these filters.

Emerging Applications

As industries grow and new technologies emerge, the demand for high-performance filtration solutions will increase. Sintered metal filters are poised to meet these challenges, with potential applications in renewable energy, advanced manufacturing, and even space exploration.

Conclusion

Sintered metal filters are a remarkable blend of durability, efficiency, and versatility. They have proven indispensable in a wide range of industries, thanks to their ability to handle extreme conditions and provide precise filtration. As technology advances, we can expect these filters to become even more integral to industrial and environmental applications.

FAQs

What materials are used in sintered metal filters?

Sintered metal filters can be made from various metals, including stainless steel, bronze, and nickel, each chosen for their specific properties and suitability for different applications.

How often should I clean my sintered metal filter?

The frequency of cleaning depends on the application and the level of contaminants. Regular inspections can help determine the optimal cleaning schedule to maintain performance.

Can sintered metal filters be customized?

Yes, sintered metal filters can be tailored to specific requirements, including pore size, shape, and material, to suit unique applications and performance needs.

Are sintered metal filters environmentally friendly?

Yes, they are durable and reusable, reducing waste compared to disposable filters. Additionally, their effectiveness in pollution control contributes to environmental protection.

What are the limitations of sintered metal filters?

While they offer many advantages, sintered metal filters can be more expensive initially and may not be suitable for applications requiring extremely fine filtration below certain micron levels.

How to Clean Sintered Metal Filters: A Comprehensive Guide

A Comprehensive Guide to Sintered Filters: Features, Production, and Benefits

Sintered Plastic Filters: A Comprehensive Guide

Sintered Metal Filters | Durable & Efficient Filtration Solutions

Sintered Activated Carbon Filters: Comprehensive Guide Introduction

Case Study: 316L Sintered Powder Filter for a Spanish Customer

Stainless Steel Cartridge Filter Housing

What maintenance is required for stainless steel cartridge filter housings?

Regular maintenance tasks for stainless steel filter housings may include replacing filter elements, cleaning or replacing gaskets and seals, inspecting for leaks or corrosion, and ensuring proper operation of valves and controls.

Sintered Powder Filters

What materials are commonly used in sintered powder filters?

Common materials include stainless steel (316L, 304L), bronze, Inconel®, Nickel, Monel®, Titanium, and other alloys. The material choice depends on the specific application's requirements.

Metal mesh filters

What are the key advantages of sintered wire mesh filter?

• High Strength: The sintered wire mesh filter exhibits excellent mechanical strength.

• Uniform Porosity: The sintering process creates a uniform pore structure for efficient filtration.

• Temperature Resistance: Suitable for applications with high temperatures.

• Easy to Clean: Can be cleaned and reused multiple times.

• Chemical Resistance: Resistant to corrosion and chemical exposure.

Porous Plastic Filter

Are sintered porous filter discs suitable for sterile filtration?

Yes, sintered porous filter discs can be designed for sterile filtration applications, especially when made from materials suitable for high-temperature and chemical sterilization methods.

What are the typical applications of sintered plastic porous filters?

Sintered plastic porous filters are used in various industries, such as pharmaceuticals, food and beverage, water treatment, automotive, aerospace, and electronics, for filtration, separation, venting, and fluidization applications.

Titanium rod filter

Discover the efficiency and versatility of Lvyuan's titanium rod filter, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Y Type filter housing

The stainless steel y strainer comprises several key components, including a housing, a multi-element filter, a reverse flushing mechanism, a differential pressure controller, and others.

Stainless steel air filter housing

Lvyuan's Stainless Steel Air Filter Housing is crafted from high-grade stainless steel, ensuring durability and corrosion resistance for extended service life. With versatile configuration options and various size choices, our housing effectively accommodates different filtration needs.

Portable filtration system

Designed for versatility and convenience, Lvyuan stainless steel Portable Filtration System offers an efficient solution for on-the-go filtration needs. With its compact and lightweight design, this system is easily transportable and can be deployed in various environments, from industrial settings to remote locations.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

Sintered titanium filter

Discover the efficiency and versatility of Lvyuan's sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Stainless steel perforated filter

Lvyuan stainless steel Perforated filter is a new type of filter material processed by combining perforated plates with several layers of square mesh (or dense mesh) through sintering.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions