The Importance of Porous PE Filter Materials in Creating Odorless and Safe Filter Elements

High-quality PE raw materials ensure odorless and safe filter elements with uniform pores that withstand higher filtration pressure.

High-Quality PE Raw Materials: The Key to Odorless and Safe Filter Elements

When it comes to filtration, the quality of the raw materials used is of utmost importance. High-quality PE raw materials play a crucial role in ensuring that filter elements are not only odorless and safe but also capable of withstanding higher filtration pressure. This blog post explores the significance of using porous PE filter materials and their impact on the overall performance of filter elements.

The Significance of Porous PE Filter Materials

Porous PE filter materials are known for their uniform pore structure, which allows for efficient filtration of various substances. This uniformity in pore size ensures that the filter element can effectively capture particles of specific sizes, making it an ideal choice for applications that require precise filtration. In addition, the high-quality PE raw materials used in the manufacturing process contribute to the overall durability and longevity of the filter element.

The Importance of Odorless and Safe Filter Elements

One of the key benefits of utilizing high-quality PE raw materials in filter manufacturing is the production of odorless and safe filter elements. This is particularly important in industries where the purity of the filtered substances is critical, such as pharmaceuticals, food and beverage, and water treatment. The use of porous PE filter materials ensures that the filtered substances remain uncontaminated and free from any undesirable odors.

Withstanding Higher Filtration Pressure

In applications that require higher filtration pressure, the integrity of the filter element is paramount. High-quality PE raw materials contribute to the structural strength of the filter element, allowing it to withstand higher filtration pressure without compromising its performance. This is particularly beneficial in industrial settings where filtration under high pressure is a common requirement.

FAQs about High-Quality PE Filter Materials

Q: What makes porous PE filter materials ideal for filtration applications?

A: The uniform pore structure of porous PE filter materials ensures efficient and precise filtration of various substances.

Q: Are filter elements made from high-quality PE raw materials safe for use in food and beverage applications?

A: Yes, filter elements made from high-quality PE raw materials are odorless and safe, making them suitable for food and beverage applications.

Q: Can filter elements withstand higher filtration pressure when made from porous PE filter materials?

A: Yes, the use of high-quality PE raw materials ensures that filter elements can endure higher filtration pressure without compromising their performance.

Conclusion

In conclusion, the use of high-quality PE raw materials in the production of porous PE filter materials is instrumental in creating odorless and safe filter elements that can withstand higher filtration pressure. These qualities make them an ideal choice for a wide range of filtration applications, ensuring the efficient and reliable removal of contaminants.

How to Clean Sintered Metal Filters: A Comprehensive Guide

A Comprehensive Guide to Sintered Filters: Features, Production, and Benefits

Sintered Plastic Filters: A Comprehensive Guide

Sintered Metal Filters | Durable & Efficient Filtration Solutions

Sintered Activated Carbon Filters: Comprehensive Guide Introduction

Case Study: 316L Sintered Powder Filter for a Spanish Customer

For company

When is Lvyuan founded?

Lvyuan was established on October 12, 2009

Sintered Powder Filters

Can sintered powder filters be customized for specific applications?

Yes, sintered powder filters can be customized based on factors such as material, shape, pore size, micron rating, and filtration requirements to suit the unique needs of different applications.

Stainless Steel Pleated Filter Cartridges

What is a Stainless Steel Pleated Filter Cartridge?

A Stainless Steel Pleated Filter Cartridge is a filtration device with a pleated design, made from high-quality stainless steel (SS 304 or SS 316L). It is used for efficient particle removal in various industrial applications.

Can these Stainless Steel Pleated Filter Cartridges be customized?

Yes, Stainless Steel Pleated Filter Cartridges are available in various sizes, materials, and filtration ratings, allowing for customization to meet specific application requirements.

Sintered mesh filters

What is the temperature range for sintered mesh filters?

Sintered mesh filters can withstand a broad temperature range, typically from -200°C to 600°C. The temperature resistance depends on the material used in the filter construction.

Titanium rod filter

Discover the efficiency and versatility of Lvyuan's titanium rod filter, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Y Type filter housing

The stainless steel y strainer comprises several key components, including a housing, a multi-element filter, a reverse flushing mechanism, a differential pressure controller, and others.

Stainless steel air filter housing

Lvyuan's Stainless Steel Air Filter Housing is crafted from high-grade stainless steel, ensuring durability and corrosion resistance for extended service life. With versatile configuration options and various size choices, our housing effectively accommodates different filtration needs.

Portable filtration system

Designed for versatility and convenience, Lvyuan stainless steel Portable Filtration System offers an efficient solution for on-the-go filtration needs. With its compact and lightweight design, this system is easily transportable and can be deployed in various environments, from industrial settings to remote locations.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

Sintered titanium filter

Discover the efficiency and versatility of Lvyuan's sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Stainless steel perforated filter

Lvyuan stainless steel Perforated filter is a new type of filter material processed by combining perforated plates with several layers of square mesh (or dense mesh) through sintering.

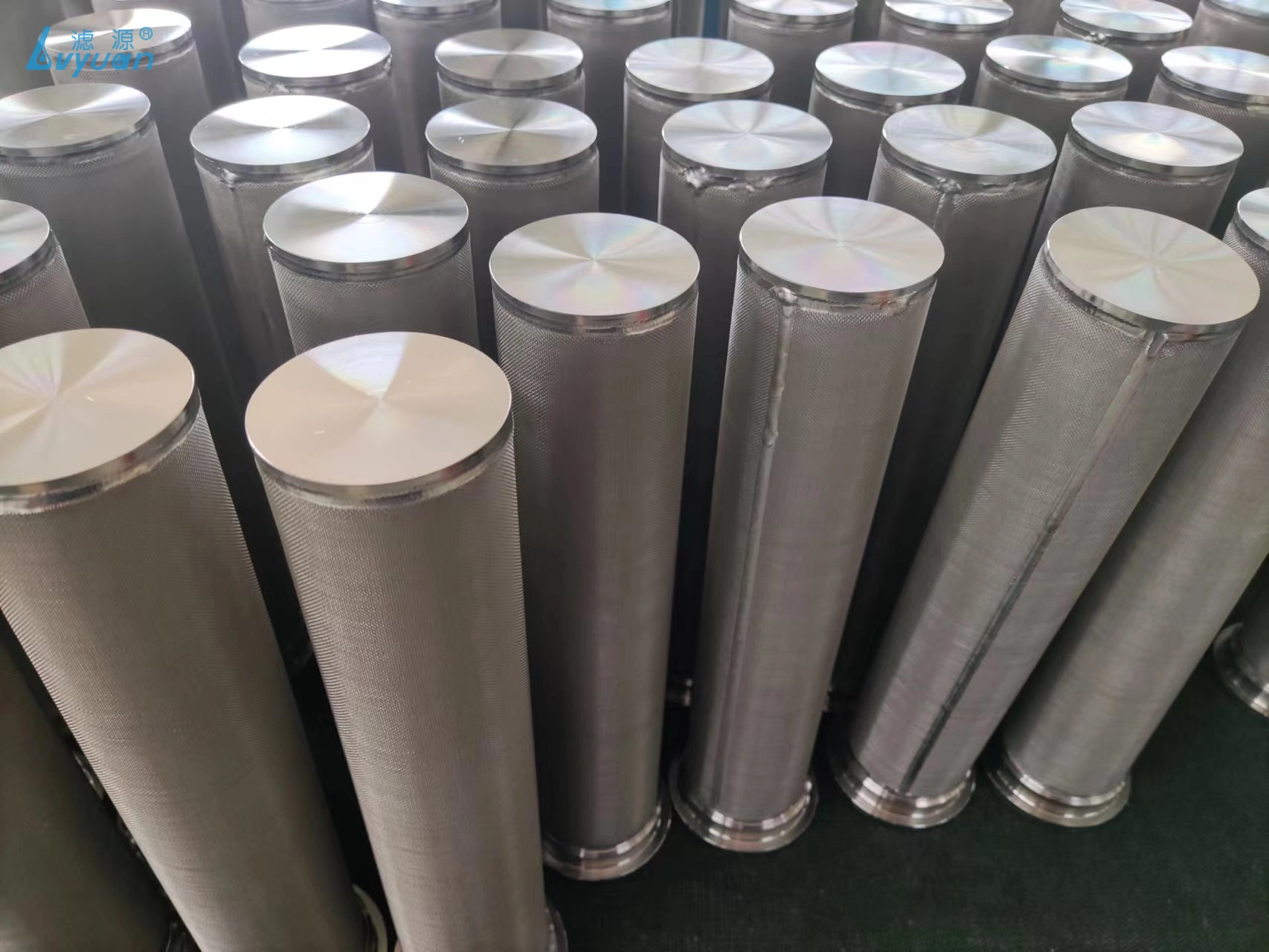

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions