Case Study: Supplying High-Quality Floor Drain Strainers to America

Discover how Lvyuan successfully supplied high-quality floor drain strainers across America in this compelling case study. Learn how our innovative drain basket solutions ensured superior durability and functionality, meeting diverse customer needs. This article showcases our dedication to quality and efficiency in providing strainer products tailored to enhance drainage systems nationwide. Explore the strategies and outcomes that solidify Lvyuan's position as a trusted leader in the floor drain strainer industry, setting benchmarks in excellence and customer satisfaction.

A client from the United States approached us with a specific need for a reliable floor drain strainer. They required a product that could effectively handle the coarse filtration of food, ensuring their operations remained hygienic and efficient. The strainer had to be durable, easy to clean, and capable of withstanding the demanding environment of a food processing facility.

Product Overview

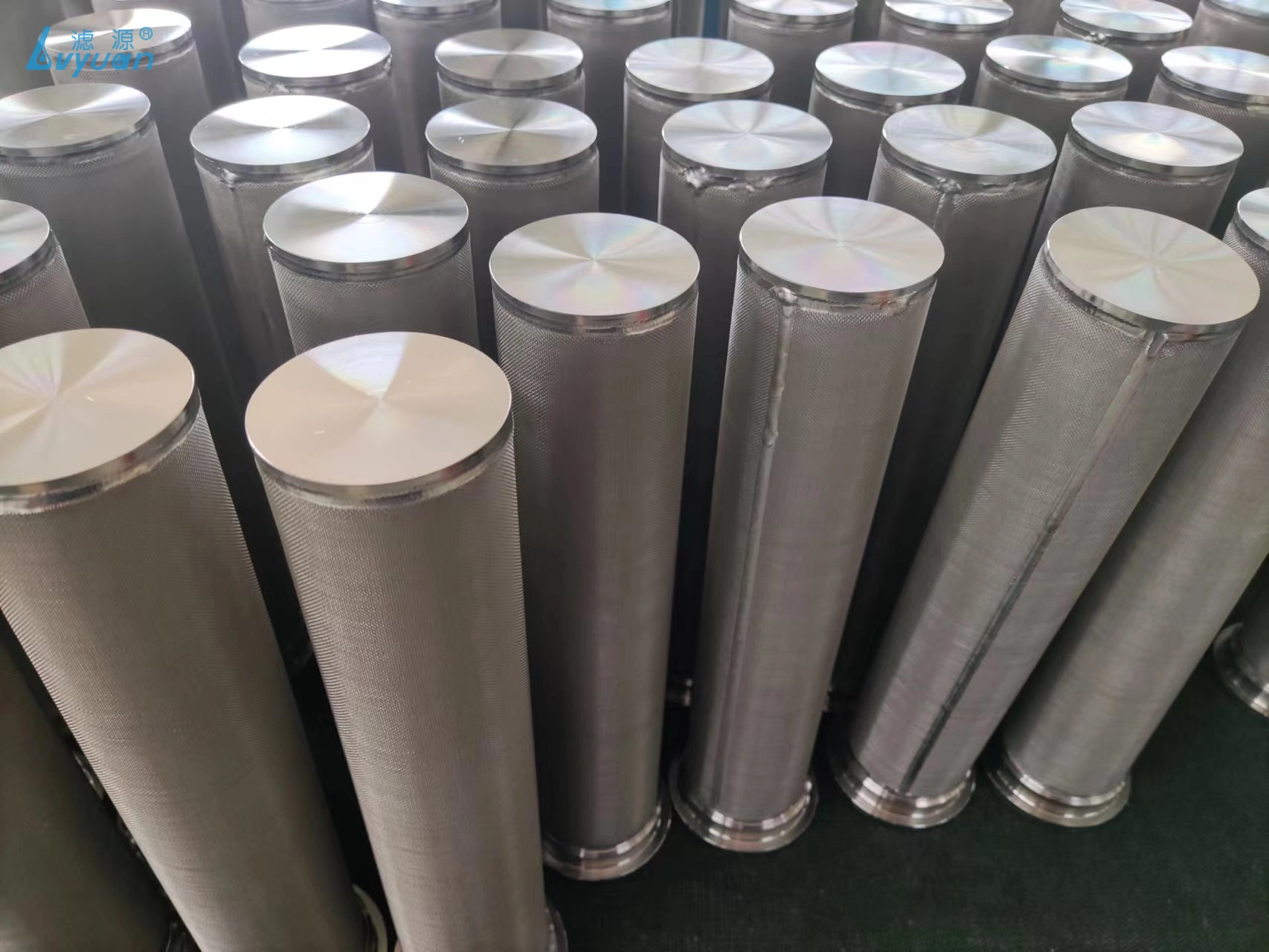

The product chosen to meet these requirements was our Floor Drain Strainer, specifically designed with the following features:

Quantity: 100 pieces

Material: 316 stainless steel

Construction: Punched 4mm stainless steel tube

Filter: Inline 100 µm stainless steel filter

Application: Coarse filtration of food oil and other liquids

Challenges

The key challenges were to ensure the strainers could:

Durability: Withstand the harsh conditions of a food processing environment, including exposure to corrosive substances.

Efficiency: Effectively filter food oil without clogging, ensuring smooth operation.

Compliance: Meet industry standards for materials used in food processing equipment.

Solution

To address these challenges, our team took the following steps:

Material Selection: We selected 316 stainless steel for its superior corrosion resistance, strength, and durability. This material is ideal for use in food processing environments, where hygiene and longevity are paramount.

Design and Construction: The strainer was designed with a punched 4mm stainless steel tube, providing ample strength and durability while allowing for efficient oil flow. The inline 100 µm stainless steel filter was integrated to handle coarse filtration, effectively trapping larger particles while allowing clean oil to pass through.

Quality Assurance: Each strainer underwent rigorous testing to ensure it met the required specifications, particularly in terms of filtration efficiency and durability. This included stress testing the filters to ensure they could withstand repeated use without degradation.

Customization and Delivery: We customized the strainers to meet the client's specific needs and coordinated closely with our logistics team to ensure timely delivery of all 100 pieces to the United States. The strainers were packaged securely to prevent any damage during transit.

Outcome

The floor drain strainers were delivered to the client in America on schedule. Upon implementation, the client reported a significant improvement in the efficiency of their food oil filtration process. The strainers not only met but exceeded their expectations in terms of durability and performance, leading to smoother operations and reduced maintenance costs.

The success of this project demonstrated our capability to supply high-quality, customized solutions that meet the specific needs of our clients in the food processing industry.

Conclusion

This case study illustrates our commitment to delivering durable, efficient, and compliant products tailored to the unique requirements of our clients. The successful deployment of the floor drain strainers in the American food processing facility highlights our ability to meet stringent industry standards and ensure customer satisfaction.

FAQs

What is the primary use of the floor drain strainer?

The floor drain strainer is used for coarse filtration of food oil and other liquids in food processing facilities.

Why was 316 stainless steel chosen for this product?

316 stainless steel was selected for its excellent corrosion resistance and durability, making it ideal for food processing environments.

How does the 100 µm filter contribute to the strainer's performance?

The 100 µm stainless steel filter effectively traps larger particles, ensuring that only clean oil passes through, which is crucial for maintaining efficient operations.

Can the floor drain strainer be customized for different applications?

Yes, the design and specifications of the floor drain strainer can be customized to meet specific requirements for various applications.

What measures are taken to ensure the product's quality before delivery?

Each strainer undergoes rigorous testing to ensure it meets the required standards for filtration efficiency, durability, and compliance with industry regulations.

How to Clean Sintered Metal Filters: A Comprehensive Guide

A Comprehensive Guide to Sintered Filters: Features, Production, and Benefits

Sintered Plastic Filters: A Comprehensive Guide

Sintered Metal Filters | Durable & Efficient Filtration Solutions

Sintered Activated Carbon Filters: Comprehensive Guide Introduction

Case Study: 316L Sintered Powder Filter for a Spanish Customer

Metal mesh filters

Can sintered wire mesh filter be used in high-pressure applications?

Yes, sintered wire mesh is suitable for high-pressure applications due to its high strength and durable structure. However, specific pressure ratings may vary based on the material and design, so it's essential to consider these factors.

Sintered Metal Filters

What materials are used in sintered metal filter?

Sintered metal filters are typically made from stainless steel, such as 304 or 316, due to its corrosion resistance and durability. Other alloys, like Hastelloy or Inconel, may also be used based on specific application requirements.

Sintered Titanium Filters

What Applications Are Sintered Titanium Filters Suitable For?

Sintered titanium filters are versatile and find applications in water treatment, gas diffusion, chemical experiments, and pharmaceutical processes due to their temperature resistance and corrosion resilience.

For products

How are sintered metal filters cleaned?

Cleaning methods for sintered metal filters include backwashing, ultrasonic cleaning, and chemical cleaning. The method depends on the type of contaminants and the filter's specifications.

For company

Lvyuan main product advantages

• Quality Assurance:

Lvyuan prioritizes quality as a cornerstone of its operations. We adhere to rigorous quality control standards throughout the manufacturing process to ensure that our products meet the highest industry standards.

• Innovative Technology:

We leverage cutting-edge technologies in the design and production of our products. By staying at the forefront of technological advancements, we provide our customers with innovative solutions that meet their evolving needs.

• Diverse Product Range:

Lvyuan offers a comprehensive and diverse range of products, catering to various industries and applications. Our extensive product portfolio allows customers to find solutions tailored to their specific requirements.

• Customization Capabilities:

Recognizing the unique needs of our customers, we provide customizable options for our products. This ensures that our clients receive tailored solutions that align with their individual preferences and applications.

• Competitive Pricing:

We are committed to offering competitive prices without compromising on quality. Our cost-effective solutions enable customers to access high-quality products at reasonable and competitive market rates.

Titanium rod filter

Discover the efficiency and versatility of Lvyuan's titanium rod filter, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Y Type filter housing

The stainless steel y strainer comprises several key components, including a housing, a multi-element filter, a reverse flushing mechanism, a differential pressure controller, and others.

Stainless steel air filter housing

Lvyuan's Stainless Steel Air Filter Housing is crafted from high-grade stainless steel, ensuring durability and corrosion resistance for extended service life. With versatile configuration options and various size choices, our housing effectively accommodates different filtration needs.

Portable filtration system

Designed for versatility and convenience, Lvyuan stainless steel Portable Filtration System offers an efficient solution for on-the-go filtration needs. With its compact and lightweight design, this system is easily transportable and can be deployed in various environments, from industrial settings to remote locations.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

Sintered titanium filter

Discover the efficiency and versatility of Lvyuan's sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Stainless steel perforated filter

Lvyuan stainless steel Perforated filter is a new type of filter material processed by combining perforated plates with several layers of square mesh (or dense mesh) through sintering.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions